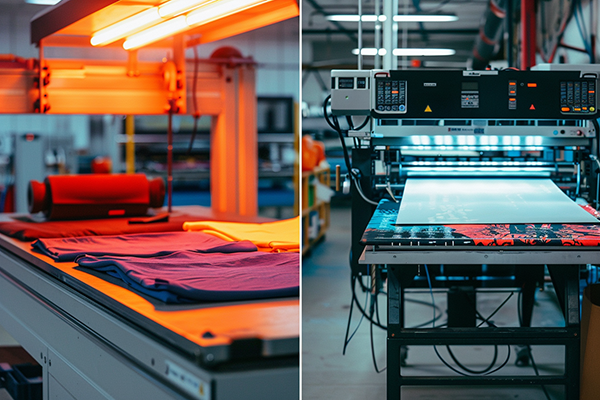

When it comes to custom clothing, durability is a crucial factor. Whether it’s for uniforms, sportswear, or personalized T-shirts, you want prints that can withstand frequent washing, stretching, and general wear. But with so many printing methods available—like screen printing1, direct-to-garment (DTG) printing2, and direct-to-film (DTF) printing3—which one offers the most lasting results?

Screen printing1 is widely considered the most durable printing method for clothing, especially for bulk orders, but advances in DTG and DTF printing have also introduced highly durable options for detailed designs and smaller batches.

In this article, we’ll compare DTG and DTF printing, explore the most durable methods for specific applications, and provide insights into selecting the right printing process.

What is the difference between DTG and DTF?

Direct-to-garment (DTG) printing2 and direct-to-film (DTF) printing3 are two of the most popular digital printing methods. While they share some similarities, they differ significantly in process, durability, and fabric compatibility.

The primary difference between DTG and DTF is that DTG prints directly onto fabric, while DTF transfers designs onto fabric using a film and adhesive powder.

DTG Printing

-

How It Works

- DTG uses a specialized printer to apply water-based inks directly onto the fabric.

- The design bonds with the fibers of the material, creating a smooth and vibrant print.

-

Best For

- Detailed, colorful designs with gradients or photo-like quality.

- Works best on 100% cotton fabrics.

-

Durability

- DTG prints are durable but can fade slightly over time, especially with improper care.

-

Limitations

- Requires pre-treated fabric to ensure ink adhesion.

- Not ideal for synthetic fabrics like polyester.

DTF Printing

-

How It Works

- DTF involves printing the design onto a special film, applying adhesive powder, and heat-pressing it onto fabric.

- The adhesive bonds the design to the fabric’s surface.

-

Best For

- Versatile applications on various fabrics, including cotton, polyester, and blends.

- Excellent for small-batch orders and detailed designs.

-

Durability

- DTF prints are highly durable, withstanding frequent washing and stretching without cracking or peeling.

-

Limitations

- Slightly thicker texture compared to DTG prints.

| Feature | DTG Printing | DTF Printing |

|---|---|---|

| Fabric Compatibility | Best on cotton | Works on cotton, polyester, blends |

| Durability | Moderate, may fade over time | High, resistant to cracking/peeling |

| Design Detail | Excellent for photo-like prints | Excellent for bold, vibrant designs |

| Texture | Soft and smooth | Slightly thicker |

DTG is ideal for intricate designs on cotton, while DTF offers superior versatility and durability across multiple fabrics.

Why is screen printing considered the most durable?

Screen printing1 has long been regarded as the go-to method for creating bold, durable designs, especially for bulk orders.

Screen printing is considered the most durable printing method because the thick layers of ink bond strongly with the fabric, making it resistant to fading, cracking, and peeling.

Key Benefits of Screen Printing

-

Ink Saturation

- The ink penetrates deeply into the fabric, creating vibrant colors that last.

-

Versatility

- Works on a variety of fabrics, including cotton, polyester, and blends.

-

Resilience

- Prints withstand frequent washing and heavy wear, making them ideal for uniforms, sportswear, and promotional items.

Limitations of Screen Printing

- Setup Costs:

- Requires creating screens for each color, making it expensive for small orders.

- Design Complexity:

- Best for simple designs with fewer colors; detailed graphics can be challenging.

Best Uses for Screen Printing

- Bulk Orders: Economical for large quantities.

- Bold, Simple Graphics: Ideal for logos, team names, and promotional merchandise.

| Feature | Performance in Screen Printing |

|---|---|

| Durability | Excellent, resists fading and cracking |

| Cost Efficiency | High for bulk orders |

| Design Detail | Limited for intricate or multi-color designs |

For long-lasting prints, especially in large quantities, screen printing remains the top choice.

Which printing method is best for small orders?

Small orders often require flexibility, cost efficiency, and quick turnaround times.

For small orders, DTF printing3 is the best option due to its affordability, versatility, and ability to produce high-quality designs without the need for complex setups.

Why DTF Excels in Small Orders

-

No Setup Costs

- Unlike screen printing, DTF doesn’t require creating stencils or screens, reducing initial costs.

-

Versatile Applications

- Can print on various fabrics, making it suitable for custom apparel or one-off designs.

-

Quick Production

- Designs can be printed and transferred quickly, making it ideal for fast delivery.

Alternative Methods for Small Orders

-

- Ideal for personalized names and numbers on sports jerseys.

- Durable but less suitable for complex designs.

-

- Works well for photo-like designs but is limited to cotton fabrics.

| Method | Best For |

|---|---|

| DTF Printing | Versatile, affordable, fast for small orders |

| Heat Transfer Vinyl (HTV) | Custom names/numbers, simple designs |

| DTG Printing | Detailed, colorful designs on cotton |

For one-off designs or limited runs, DTF offers the perfect balance of quality and affordability.

How to maintain durability in printed clothing?

No matter which printing method you choose, proper care5 is essential for maintaining the durability of your designs.

Tips for Long-Lasting Prints

-

Wash Inside Out

- Turn garments inside out before washing to reduce friction on the design.

-

Use Cold Water

- Hot water can cause prints to crack or fade over time.

-

Avoid High Heat Drying

- Air-dry or use a low-heat setting to prevent shrinking or damaging the print.

-

Avoid Harsh Detergents

- Use mild detergents to preserve the integrity of both the fabric and the print.

-

Iron Carefully

- Never iron directly on the print; use a protective cloth or iron the garment inside out.

| Care Step | Why It’s Important |

|---|---|

| Wash Inside Out | Reduces friction and preserves print quality |

| Use Cold Water | Prevents cracking or fading |

| Avoid High Heat Drying | Maintains fabric and print integrity |

Proper care significantly extends the lifespan of printed garments, ensuring they look great even after repeated use.

Conclusion

The most durable printing methods depend on the fabric, design complexity, and intended use. Screen printing leads in durability for bulk orders, while DTF offers exceptional versatility and lasting results across various fabrics. DTG excels in creating detailed designs, though it’s best for cotton fabrics. By understanding the strengths and limitations of each method, you can choose the right printing solution for your needs and maintain your garments with proper care to ensure long-lasting quality.