Making T-shirts is not only the process of creating a fashion item, it is also an expression of art and personality. In this process, designers are able to transform their creativity and imagination into actual wearable clothing, providing people with the opportunity to express their own style. At the same time, as a basic garment in daily life, the design and production of T-shirts embody the combination of practicality and comfort, meeting people’s daily wear needs.

In addition, the production of T-shirts is also a means of conveying brand value and cultural concepts. Through unique designs and customized elements, brands are able to showcase their unique style and concepts on T-shirts and establish an emotional connection with consumers. At a technical level, making T-shirts also involves innovation in fabric selection, printing technology and production processes, which are all manifestations of technological progress in the clothing manufacturing industry.

All in all, making T-shirts is a process that integrates creativity, practicality, brand culture and technological innovation. It not only produces daily clothing, but also a way of spreading culture and fashion.

Design Phase

The design stage is a key link in the T-shirt production process. It not only determines the appearance and style of the T-shirt, but also ensures the consistency of the design with the brand concept and market positioning. At this stage, the designer’s creativity and visual imagination are crucial. They need to make careful choices between styles, colors, patterns and decorative elements to create products that are both beautiful and marketable.

Additionally, the design phase is an important time to consider practicality and comfort. Designers must ensure that the fabrics and styles chosen are appropriate for the target audience while providing comfort and functionality. For example, athletic T-shirts may require the use of more breathable fabrics, while fashion styles may focus on unique patterns and cuts.

The design phase is also about production feasibility. Technical drawings and detailed production instructions ensure that the production team can accurately realize the designer’s vision. The accuracy and meticulousness of this stage directly affects production efficiency and the quality of the final product.

In general, the design stage is an integral part of the T-shirt production process. It combines art and practicality to ensure the beauty, comfort and market competitiveness of the final product.

Concepts and inspiration collection:

The designer first determines the basic concept of the design. This may include researching fashion trends, audience preferences, cultural elements, etc.

Inspiration can come from a variety of sources, such as fashion magazines, works of art, historical clothing, the natural environment, and even social events and pop culture.

Design Sketch:

After determining the basic concept, the designer will begin to draw preliminary design sketches.

These sketches will show the basic shape, style (such as crew neck, V-neck, long sleeve, short sleeve, etc.), pattern layout and color scheme of the T-shirt.

Choose fabric and color:

Designers need to choose the right fabric according to the design of the T-shirt. Different fabrics (such as pure cotton, polyester-cotton blend, bamboo fiber, etc.) have different textures and wearing feelings.

Color selection is also an important part of this stage. Designers will consider the combination of different colors and performance on fabrics.

Detailed design:

Based on the preliminary sketch, the designer will further refine the design and add more details.

This may include specific graphic designs, text, logos, and any special decorative elements.

Create technical drawings:

After completing the design sketch, the designer produces detailed technical drawings that contain the necessary dimensions, seams, and other technical details to guide the production process.

Technical drawings will also include specific instructions for production, such as the type of stitching, how the fabric should be cut.

Sample production and modification:

Making samples based on technical drawings is an important step to test the effect of the design in actual production.

Several modifications may be required after the sample is produced to ensure that the design is accurately realized and meets the expected results.

Fabric Selection

Choosing T-shirt fabric is an important decision-making process, which directly affects the texture, comfort and durability of the final product. Here are several common T-shirt fabrics and their characteristics:

Pure cotton:

Pure cotton is one of the most commonly used T-shirt fabrics and is popular for its softness, comfort, and breathability.

It is skin-friendly and suitable for sensitive skin types, but is prone to wrinkles and shrinkage.

Polyester-cotton blend:

Polyester-cotton blends blend cotton and polyester together, combining the best of both worlds.

This fabric is wear-resistant, easy to care for, and less likely to wrinkle and shrink than pure cotton.

bamboo fiber:

Bamboo fiber fabrics are prized for their softness, antibacterial and eco-friendly properties.

It’s breathable and suitable for hot climates, but may not be as durable as pure cotton.

Modal:

Modal is an advanced man-made fiber known for its softness and high elasticity.

It is hygroscopic and comfortable, but is usually more expensive.

Of course, these are just a few of the fabrics suitable for making T-shirts. When choosing fabrics, you also need to consider the intended use of the T-shirt. For example, a sports T-shirt may require a more breathable fabric, while a fashion T-shirt may focus more on look and feel. In addition, the pre-treatment of the fabric is also important, such as pre-shrinking to ensure that the garment retains its shape after washing, while dyeing involves color selection and color fixation. Correct fabric selection and pre-treatment can not only improve the overall quality of the T-shirt, but also enhance its market appeal.

Cut fabric

Cutting fabric is a delicate and critical step in the T-shirt making process. It involves cutting the fabric into various parts of the garment according to design drawings and patterns. Here is a detailed description of this step:

Preparation:

Before starting to cut, you need to prepare the tools required for cutting, such as cutting knives, scissors, cutting boards, rulers, etc.

The fabric needs to be laid flat first to ensure there are no wrinkles or stretches to ensure accurate cutting.

Drawing laying:

Place the designed drawing on the fabric. These drawings contain the shapes and sizes of various parts of the T-shirt, such as front body, back body, sleeves, etc.

To maximize fabric utilization, drawings need to be carefully arranged to reduce waste.

Marking and underlining:

Mark the outline of the drawing on the fabric, this can be done by drawing lines or using tailor’s powder.

Mark seam lines and other important sewing instructions where needed.

Crop:

Use a trimmer or scissors to cut precisely along the marked lines.

Keep your hands steady during the cutting process to ensure smooth and neat cutting lines.

Check and adjust:

After cutting is complete, check the size and shape of each part to make sure they match the design drawing.

Make fine adjustments if necessary to make sure everything matches up perfectly.

Cutting is a process that requires precision and care because once you get it wrong, it may not be corrected. Correct cutting not only affects the appearance of the T-shirt, but also affects the smooth progress of subsequent sewing steps. Therefore, this step is very critical to ensure the final quality and appearance of the T-shirt.

Printing and decoration (if required)

In the T-shirt production process, printing and decoration are important steps that give the garment a unique personality and style. If the design contains graphics or text, the following is a description of the printing and decoration process:

Pattern design confirmation:

Before printing begins, the final version of the graphic design needs to be confirmed. This includes the size, color, placement of the pattern or text, and the specific details used for printing.

Choose printing technology:

Choose the appropriate printing technology based on the characteristics of the pattern and the type of fabric. Common printing technologies include screen printing and thermal transfer printing.

Screen printing is suitable for high-volume production and creates long-lasting, vibrant patterns on fabrics.

Thermal transfer printing is suitable for complex patterns and color gradients, suitable for small batches or personalized designs.

Prepare printing tools and materials:

Prepare the required printing materials, such as screen printing plates, ink, transfer paper, etc.

Ensure all tools and materials meet design requirements and quality standards.

To print:

Before printing, lay the fabric flat and secure it to avoid movement during printing.

Printing is carried out strictly in accordance with the predetermined pattern position and technical requirements. Throughout the entire process, precision and consistency need to be maintained to ensure the printing quality of each T-shirt.

Post-processing and quality checks:

After printing is completed, the printed part undergoes necessary post-processing, such as heat curing or cooling, to ensure the fixation and durability of the pattern.

Quality checks are performed on the print results to ensure that the pattern is clear, the colors are correct and there are no defects.

Printing and decoration are not just technical processes of adding patterns to fabrics, it also involves the fine polishing of design details and strict control of quality. The successful execution of this step can significantly improve the overall appearance and appeal of the T-shirt, making it a unique fashion item.

sewing

Sewing is a core part of the T-shirt making process and involves assembling cut fabric parts together to form a complete garment. Here is a detailed description of the sewing process:

Prepare to sew:

Before starting to sew, you need to prepare a sewing machine and other sewing tools, such as needle and thread, scissors, sewing clips, etc.

Make sure that all cut fabric parts are intact and that the size and shape match the design requirements.

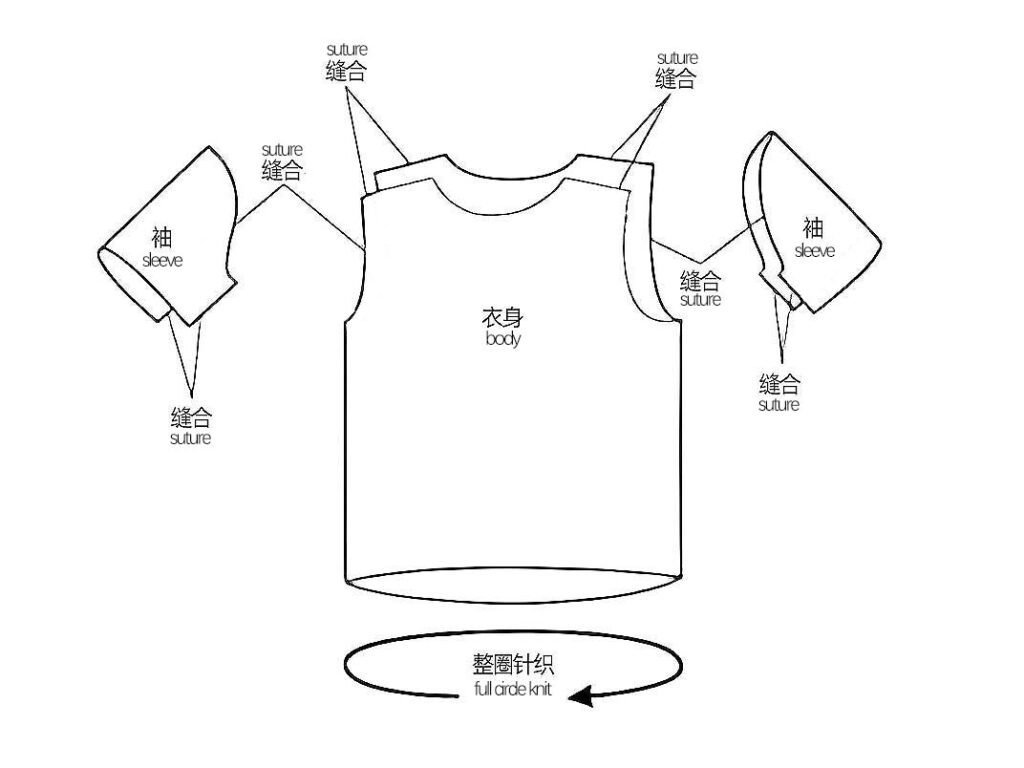

Assemble the main components:

Place the front and back body pieces together, aligning them correctly, and sew their side and shoulder seams.

Next, sew the sleeves to the body. This step requires precision to ensure the sleeves lie flat and are wrinkle-free.

To sew the neckline, cuffs and hem:

Work on the neckline, which may include stitching the collar or adding a tie.

Sew the cuffs to make sure they are the right size and comfortable.

Sew the hem, which may include straight stitching or adding an elastic edge.

Detail processing and reinforcement:

Check all sutures to make sure they are smooth and tight.

Reinforce areas prone to wear and tear, such as collars and cuffs.

quality inspection:

After sewing is completed, the entire T-shirt is inspected for quality to ensure that all parts are assembled correctly and there are no missing seams or damage to the fabric.

Check the overall appearance of the T-shirt to make sure it meets design standards and is true to size.

The sewing process requires precision technique and attention to detail. Correct sewing not only affects the appearance of a T-shirt, but also determines its comfort and durability. This step is crucial to ensure the overall quality and wearing experience of the T-shirt.

Post-processing and quality control

In the later stages of T-shirt production, post-processing and quality control are critical steps to ensure that the finished product meets standards and expectations. Below is a detailed description of these processes:

Post-processing:

- Cleaning: The finished T-shirts are cleaned first. This step removes any stains, dust, or loose fibers that may have been left behind during the making process. Washing also helps test the water resistance of fabrics and prints.

- Ironing: After washing, the T-shirt needs to be ironed to remove any wrinkles and ensure the garment lies flat. Ironing not only improves the appearance of your T-shirt, it is also an important step in giving the garment its final shape.

- Other treatments: If necessary, other post-treatments may also be performed, such as softening, anti-wrinkle treatments or special functional coatings.

quality inspection:

- Check the sewing quality: Check all stitching lines to make sure the stitches are smooth, firm and not loose or missing.

- Size accuracy: Check the design specifications to ensure that the size of the T-shirt is accurate and meets the standards. This includes the length, width and sleeve length of the garment.

- Printing and pattern inspection: Check the printing quality to ensure that the pattern is clear, the color is correct and there is no discoloration or blurring.

- Overall inspection: Check the overall look and feel of the T-shirt to make sure there are no flaws such as fabric damage, color differences or stains.

Post-processing and quality control steps are critical to ensuring the final quality of the T-shirt. They not only improve the appearance and wearing experience of clothing, but also ensure the durability and market competitiveness of the product. Through these meticulous processes, manufacturers are able to deliver high-quality, flawless garments to customers.

packaging and distribution

In the T-shirt production process, the packaging and distribution stages are key to getting the finished product to the end user. Below is a detailed description of these steps:

Package:

- Protective Packaging: After completing all production steps, T-shirts need to be properly packaged to protect the clothing from contamination and damage during transportation. This usually includes plastic bags or paper packaging to protect against dust, moisture and other potential contaminants.

- Branding and Logo: Packaging is also an opportunity for branding. Printing brand logos, washing instructions, sizing information, etc. on packaging materials not only provides necessary product information, but also increases the visibility and recognition of the brand.

- Environmental considerations: For sustainability-focused brands, using recyclable or biodegradable packaging materials is a trend to reduce environmental impact.

distribution:

- Logistics planning: Develop reasonable logistics and distribution plans based on order requirements. This may include domestic and international shipping, as well as using a variety of shipping methods such as land, air or sea.

- Delivery to retailers and customers: Safely and efficiently ship T-shirts to retail stores or distribute directly to customers purchasing online. This process requires precise logistics tracking and time management to ensure timely delivery.

- Inventory management: For mass-produced T-shirts, reasonable inventory management is an important aspect of the distribution process to ensure that the needs of different markets and customers are met.

Packaging and distribution are not just about shipping physical products, they are an important part of brand value and customer satisfaction. Through careful packaging and efficient distribution strategies, brands can enhance customer experience and enhance market competitiveness.

How to find the perfect t-shirt manufacturer?

At Modaknits, our state-of-the-art T-shirt manufacturing technology is the pride and hallmark of our brand. We are committed to combining the advantages of traditional craftsmanship and modern technology to create high-quality T-shirts that are both comfortable and durable.

We carefully select high-quality fabrics such as pure cotton and bamboo fiber to ensure the comfort and durability of each T-shirt. During the cutting stage, we use precise technology and experienced craftsmanship to ensure that each piece of fabric is cut correctly and perfectly fits the design drawings.

In terms of printing and decoration technology, we use advanced screen printing and digital direct-injection printing technology to make the pattern clear and vivid and the color lasting. During the sewing process, we pay attention to details and ensure that every stitch and thread is accurate to improve the overall quality and appearance of the product.

Finally, during the post-processing and quality control stages, we ensure each T-shirt meets our high standards through rigorous inspection. From design to finished product, every step of Modaknits reflects our commitment to superior quality and pursuit of fashion innovation.

Final Words

Modaknits focuses on standard sizes and unique designs of T-shirts to strengthen its brand influence. Our logo design is carefully positioned to emphasize the brand story and professionalism.