| Fabric name | Lycra |

| Fabric also known as | Spandex, elastane |

| Fabric composition | Polyether-polyurea copolymer |

| Commonly used in | Underwear, socks, bras, sports bras, bike shorts, yoga pants, hiking apparel, motion capture suits |

| Fabric breathabilityn | High breathability |

| Moisture-wicking abilities | High |

| Heat retention abilities | Low |

| Stretchability (give) | Extraordinarily high |

| Prone to pilling/bubbling | High |

| Country where fabric was first produced | United States |

| Biggest exporting/producing country today | China |

| Recommended washing temperatures | Warm or cold |

What is Lycra Fabric?

Lycra, also known as spandex or elastane, is a highly elastic synthetic fiber made from polyurethane. Celebrated for its exceptional stretch and recovery, Lycra is extensively used in various applications, including sportswear, swimwear, and everyday clothing.

Origin and Source of Lycra Fibers

Lycra fibers are derived from polyurethane, a polymer created from polyols and diisocyanates. This synthetic process enables the production of fibers with remarkable elasticity and strength.

Historical Significance and Modern Usage

Developed by DuPont in the late 1950s, Lycra revolutionized the textile industry with its superior elasticity and durability. Initially used in corsetry to replace rubber, it quickly found applications in sportswear, fashion, and medical textiles. Today, Lycra is a staple in many garments, enhancing comfort and performance.

Lycra Fabric Today

Modern Lycra production continues to grow, with significant contributions from the United States, China, and South Korea.

At Modaknits, we utilize advanced technology and sustainable practices to create high-quality Lycra apparel, meeting diverse client needs.

What Makes Lycra Fabric Unique?

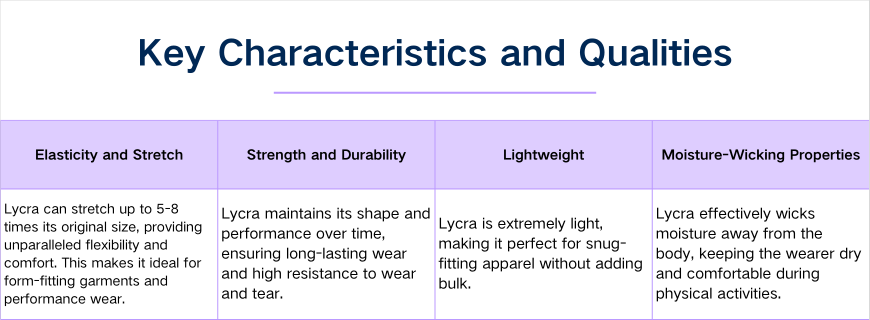

Key Characteristics And Qualities

- Elasticity and Stretch: Lycra can stretch up to 5-8 times its original size, offering exceptional flexibility and comfort. This stretchability is ideal for form-fitting garments and performance wear, allowing for a wide range of motion without losing shape.

- Strength and Durability: Lycra maintains its shape and performance over time, ensuring long-lasting wear and high resistance to wear and tear. This durability is crucial for activewear and everyday clothing that undergo frequent use.

- Lightweight: Lycra is extremely light, making it perfect for snug-fitting apparel without adding bulk. This quality is particularly advantageous in sportswear and activewear, where lightness contributes to comfort and performance.

- Moisture-Wicking Properties: Lycra effectively wicks moisture away from the body, keeping the wearer dry and comfortable during physical activities. This moisture management is essential for maintaining comfort and preventing chafing during exercise or in hot climates.

Comparison with Other Fabrics

Lycra vs Cotton

Lycra offers greater elasticity and faster drying compared to cotton, making it more suitable for activewear.

Lycra vs Nylon

While nylon is durable and lightweight, Lycra provides superior stretch and recovery, enhancing fit and flexibility.

Lycra vs Polyester

Polyester is durable and cost-effective, but Lycra offers better fit, flexibility, and moisture management.

How is Lycra Fabric Made?

Lycra fabric, renowned for its exceptional elasticity and durability, undergoes a meticulous production process to ensure its superior performance and versatility. Here’s an overview of how Lycra is made, emphasizing its unique manufacturing methods:

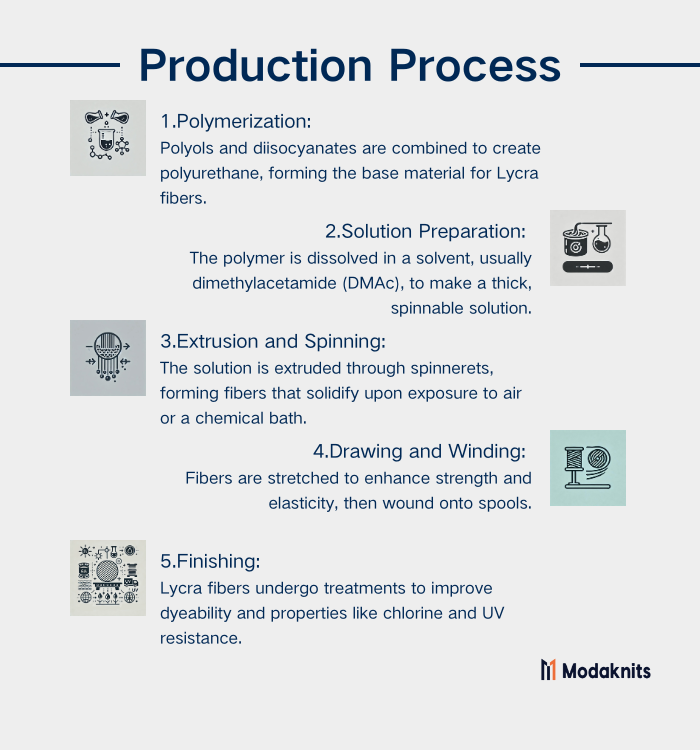

Production Process

- Polymerization: Production begins with the polymerization of polyurethane, where polyols and diisocyanates are combined to create long polymer chains that form the base material for Lycra fibers.

- Solution Preparation: The polymer is dissolved in a solvent, typically dimethylacetamide (DMAc), to create a thick, viscous solution. This step is essential for transforming the solid polymer into a spinnable liquid.

- Extrusion and Spinning: The viscous solution is extruded through spinnerets, forming thin fibers that solidify when exposed to air or a chemical bath. This process gives the fibers their initial strength and elasticity.

- Drawing and Winding: The fibers are stretched to several times their original length to enhance their strength and elasticity. They are then wound onto spools, ready for further processing.

- Finishing: The Lycra fibers undergo finishing treatments to improve their dyeability and other properties, such as resistance to chlorine and UV light. These treatments ensure the fabric meets specific performance requirements before being woven or knitted into final products.

Regions Known for Lycra Production

- United States: The U.S. is a significant producer of Lycra, with advanced production facilities focusing on innovation and sustainability.

- China: Leading in large-scale Lycra production, China utilizes advanced technology and efficient manufacturing processes, making it a key player in the Lycra market.

- South Korea: Known for high-quality Lycra production, South Korea emphasizes technological advancements and strict quality control measures.

These regions contribute significantly to the global supply of Lycra, ensuring high-quality production through innovative and sustainable practices.

What are the Types of Lycra Fabric?

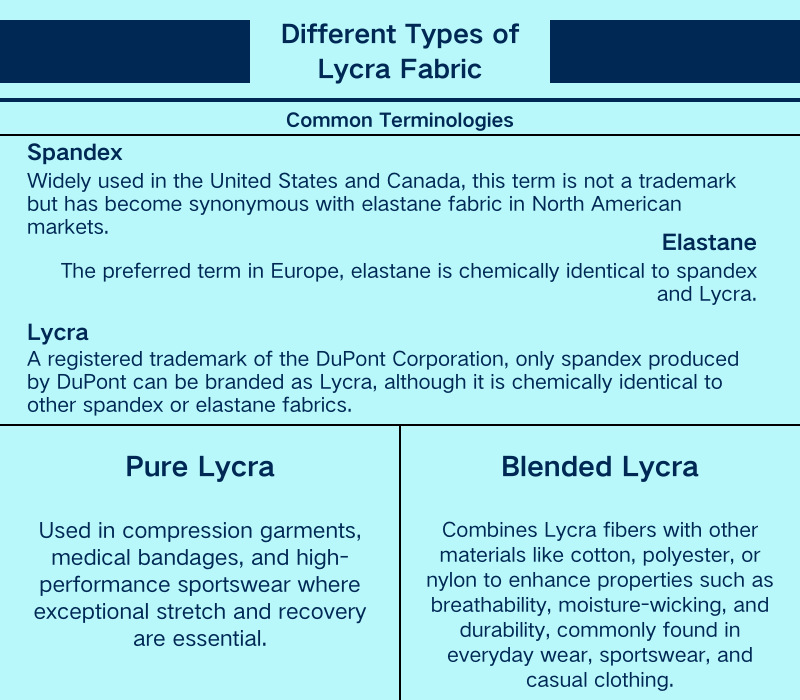

Lycra fabric, also known as spandex or elastane, can be categorized based on its applications and blending with other fibers. Despite different production methods, the chemical composition remains consistent. Various terms are used to describe this versatile fabric:

Common Terminologies

Spandex:

- Widely used in the United States and Canada.

- An anagram of “expands,” this term is not a trademark but has become synonymous with elastane fabric in North American markets.

Elastane:

- The preferred term in Europe.

- Considered the most chemically accurate name for this fabric, elastane is identical to spandex and Lycra in terms of composition and properties.

Lycra:

- A registered trademark of the DuPont Corporation.

- Only spandex produced by DuPont can be branded as Lycra, although it is chemically identical to other spandex or elastane fabrics.

Types and Their Applications

Pure Lycra:

- Description: Composed entirely of Lycra fibers, offering maximum elasticity and comfort.

- Applications: Commonly used in compression garments, medical bandages, and high-performance sportswear where exceptional stretch and recovery are essential.

Blended Lycra:

- Description: Combines Lycra fibers with other materials like cotton, polyester, or nylon to enhance properties such as breathability, moisture-wicking, and durability.

- Applications: Found in everyday wear, sportswear, and casual clothing, providing a balance of comfort and functionality.

These types of Lycra fabric demonstrate its versatility and crucial role in enhancing the functionality and comfort of various textile products.

How is Lycra Fabric Used?

Lycra fabric’s exceptional stretch, durability, and lightweight nature make it ideal for a wide range of applications, from activewear to industrial uses. Its unique properties, including elasticity, strength, and moisture-wicking capabilities, have made it a staple in various industries.

Apparel Applications

Activewear: Lycra is essential in activewear, providing the flexibility and comfort needed for high-performance activities.

- Leggings: Offer superior stretch and recovery, perfect for yoga, running, and fitness routines.

- Sports Bras: Ensure a secure fit and robust support, crucial for intense workouts.

- Compression Garments: Enhance blood circulation and muscle support, commonly used by athletes and in physical therapy.

Swimwear: Lycra’s quick-drying and chlorine-resistant properties make it ideal for swimwear.

- Swimsuits: Provide a snug fit and freedom of movement, vital for swimming and water sports.

- Rash Guards: Protect the skin from UV rays and abrasions while maintaining flexibility in the water.

Everyday Wear: Lycra is frequently blended with other fibers to enhance everyday clothing items.

- Jeans: Add stretch for better fit and comfort.

- Underwear: Provide a snug fit and ease of movement.

- Fitted Shirts: Maintain shape and a close fit without restricting movement.

Medical Applications

- Compression Bandages and Stockings: Provide necessary stretch and support for medical applications, ensuring effective therapeutic use.

- Support Garments: Used in therapeutic clothing for improved blood circulation and muscle support, aiding in recovery and physical health.

Industrial Applications

- Automotive Textiles: Used in seat covers and interior fabrics to provide elasticity and durability, enhancing comfort and longevity in automotive interiors.

- Cleaning Products: Incorporated into cleaning cloths and wipes, Lycra provides durability and elasticity, making these products more effective and long-lasting.

Lycra fabric’s applications across these sectors highlight its versatility and performance, making it a preferred choice for both manufacturers and consumers.

How Much Does Lycra Fabric Cost?

The cost of Lycra fabric varies based on several factors, including fiber quality, weave type, and region of production. Here are the typical price ranges for different qualities of Lycra fabric, with prices based on the US market:

Cost Implications

Basic Lycra Fabric: Generally costs between $5 to $10 per yard. This range is suitable for casual clothing and basic activewear.

High-Quality Lycra Fabric: Premium Lycra, featuring finer fibers and a smoother texture, typically ranges from $15 to $30 per yard. This fabric is used in luxury garments and high-performance activewear.

Specialty Lycra Fabric: Advanced or blended Lycra fabrics can exceed $30 per yard. These are often used in high-fashion clothing and specialized applications requiring superior elasticity and durability.

Lycra Fabric Costs in China

In China, Lycra fabric is generally more affordable due to lower production and labor costs. High-quality Lycra fabric in China can range from $3 to $10 per yard, providing a significant cost advantage for brands looking to source this versatile material.

At Modaknits, we leverage this cost advantage to offer competitive pricing without compromising on quality. Our extensive network of suppliers and commitment to sustainable practices ensure that our clients receive the best value for their investment.

Understanding these price ranges and quality indicators will help you select the best Lycra fabric for your specific needs, whether for everyday use or high-end applications.o $10 per yard. This offers a significant cost advantage for brands looking to source Lycra fabric.

How Does Lycra Fabric Impact the Environment?

Lycra fabric, known for its exceptional elasticity and durability, poses several environmental challenges. Understanding these impacts is essential for making informed choices about its production and use.

Environmental Considerations

- Production Impact: Lycra production is energy-intensive and relies heavily on petroleum-based raw materials, generating significant chemical waste that can be harmful to the environment if not properly managed.

- Biodegradability: Lycra is not biodegradable, meaning it does not break down naturally over time. This contributes to long-term waste in landfills, posing challenges for waste management and environmental sustainability.

- Recycling Initiatives: Efforts to recycle Lycra and improve sustainable production methods are ongoing. Innovations in textile recycling aim to reduce the environmental footprint by recovering and reusing fibers from discarded garments. These initiatives, although in early stages, show promise in making Lycra production more sustainable.

Innovations in Sustainable Production

- Advances in Eco-Friendly Production: Research is focusing on reducing the environmental impact of Lycra production through the use of eco-friendly solvents and energy-efficient processes. These advancements help lower the carbon footprint and minimize chemical waste, making Lycra production more sustainable.

- Use of Sustainable Blends: Blending Lycra with other sustainable fibers such as organic cotton or recycled polyester can further reduce the overall environmental impact. These blends combine Lycra’s desirable properties with the eco-friendly attributes of other fibers, resulting in more environmentally responsible textiles.

Modaknits’ Commitment to Sustainability

At Modaknits, we are dedicated to implementing and promoting sustainable practices in our Lycra apparel manufacturing. Our collaboration with ethical suppliers and the use of eco-friendly production methods significantly reduce our environmental impact. We support humane labor practices, sustainable sourcing, and the use of certified sustainable materials.

Our Practices Include:

- Premium Materials: Sourcing high-quality Lycra fibers to create durable and comfortable garments.

- Eco-Friendly Manufacturing: Utilizing environmentally responsible methods to minimize waste and resource consumption.

- Commitment to Quality and Sustainability: Ensuring that our products meet the highest standards for both quality and environmental responsibility.

By prioritizing these values, we aim to produce high-quality Lycra garments that meet the demands of our customers while contributing positively to the environment.

Certifications and Quality Indicators for Lycra Fabric

When purchasing Lycra fabric, understanding key quality indicators and verifying authenticity through recognized certifications is crucial.

Quality Indicators

- Stretch and Recovery: High-quality Lycra should maintain its shape and elasticity after stretching, ensuring long-lasting performance and comfort in garments.

- Durability: Lycra fabric should withstand wear and tear, maintaining its elasticity and integrity through repeated use, which is essential for activewear and performance garments.

Certifications and Authenticity

- OEKO-TEX® Standard 100: This certification ensures that the fabric is free from harmful substances and safe for human use. It provides confidence that the Lycra fabric meets high safety and environmental standards, making it suitable for sensitive skin and prolonged wear.

- Global Recycled Standard (GRS): This certification ensures that the recycled content in Lycra meets specific environmental and social criteria, supporting sustainable practices and verifying the authenticity and quality of recycled Lycra fibers.

Modaknits’ Commitment to Quality

At Modaknits, we excel in crafting high-quality Lycra apparel using advanced technology and sustainable practices. Our dedication to excellence ensures that every garment is made from premium Lycra fibers, providing unmatched comfort and durability. We prioritize eco-friendly methods to meet the growing demand for sustainable fashion.

We welcome brands to partner with Modaknits in producing top-tier Lycra apparel. For more information or to request our product catalog, please contact us.

Your vision, our expertise – creating exceptional Lycra apparel together.