Finding a reliable yoga pants manufacturer is a crucial step in building a successful activewear brand. With the growing popularity of yoga and athleisure, the demand for high-quality, stylish, and functional yoga pants has surged. However, choosing the right manufacturer involves more than just finding the cheapest option—it requires a balance of quality, cost, and reliability.

To find a good yoga pants manufacturer, you need to research potential suppliers, evaluate their capabilities, test product quality, and build a strong partnership. A thorough vetting process ensures you align with a manufacturer that meets your brand’s standards and goals.

This guide walks you through the essential steps to finding the perfect yoga pants manufacturer.

Step 1: Define your requirements

Before you begin your search, clearly outline what you need from a manufacturer.

1. Decide on your product features

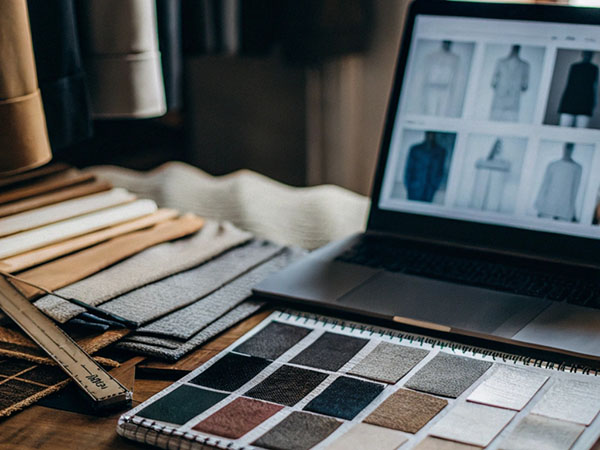

Identify the specific qualities and designs you want for your yoga pants:

- Material: Fabrics like nylon-spandex or polyester-spandex blends are popular for their stretch, durability, and moisture-wicking properties.

- Fit: High-waisted, cropped, full-length, or flare styles.

- Features: Pockets, mesh panels, or seamless construction for added functionality and appeal.

- Purpose: Focus on performance, comfort, or eco-friendly designs based on your target audience.

Pro Tip: Create a detailed product specification sheet to share with potential manufacturers.

2. Determine your order size

Establish your expected order volume, including minimum order quantities (MOQs). Small brands or startups may prefer manufacturers with low MOQ requirements.

Step 2: Research potential manufacturers

Once you know what you’re looking for, start researching manufacturers who specialize in activewear and yoga apparel.

1. Use online directories

Platforms like Alibaba, Sewport, and Maker’s Row1 are excellent for finding manufacturers. These sites provide reviews, ratings, and contact details for suppliers.

2. Attend trade shows

Industry events like MAGIC Las Vegas, Texworld USA, or ISPO Munich2 allow you to meet manufacturers, view samples, and discuss your requirements face-to-face.

3. Network through industry groups

Join forums, LinkedIn groups, or Reddit threads for fashion entrepreneurs. Recommendations from experienced designers can lead you to reliable suppliers.

4. Consider local vs. overseas manufacturers

Decide whether to work with a domestic manufacturer or source from countries like China, Vietnam, or India3. Each option has pros and cons:

- Local manufacturers: Easier communication, faster shipping, and smaller MOQs.

- Overseas manufacturers: Lower production costs and access to a broader range of materials.

Pro Tip: If you choose an overseas manufacturer, ensure they have experience exporting to your country.

Step 3: Evaluate manufacturers

After narrowing down your list of potential manufacturers, evaluate their capabilities and reliability.

1. Request product samples

Samples are essential for assessing fabric quality, fit, and craftsmanship. Look for:

- Durable stitching and reinforced seams.

- Stretch and recovery of the fabric.

- Consistency in color and pattern application.

2. Check certifications

Verify that the manufacturer complies with industry standards, such as ISO 9001, OEKO-TEX Standard 100, or WRAP4.

3. Research their portfolio

Ask for examples of their previous work, especially with yoga or activewear brands. Manufacturers with relevant experience are more likely to understand your requirements.

4. Assess communication

Clear and timely communication is critical. Test their responsiveness and willingness to answer your questions during initial interactions.

Step 4: Understand their production capabilities

Ensure the manufacturer can meet your current and future production needs.

1. Confirm their MOQ

Choose a manufacturer whose minimum order quantity aligns with your budget and sales projections.

2. Ask about lead times

Discuss their production timeline to ensure it aligns with your launch schedule. Reliable manufacturers should provide realistic deadlines and adhere to them.

3. Check scalability

Partner with a manufacturer who can scale production as your brand grows. This ensures you can meet increased demand without switching suppliers.

Step 5: Discuss pricing and terms

Understanding pricing and establishing clear terms is crucial for a successful partnership.

1. Request detailed quotes

Ask for an itemized breakdown of costs, including:

- Material and labor expenses.

- Customization fees (e.g., logo printing or embroidery).

- Shipping and taxes.

2. Negotiate payment terms

Manufacturers often require a deposit (30–50%) upfront. Negotiate payment schedules that balance cash flow and trust.

3. Review contracts

Ensure the agreement covers key points, such as:

- Intellectual property protection for your designs.

- Quality assurance processes.

- Terms for handling defects or delays.

Step 6: Test the partnership with a trial order

Before committing to large-scale production, place a small trial order to evaluate the manufacturer’s performance.

During the trial:

- Monitor communication and adherence to deadlines.

- Inspect the final products for quality and consistency.

- Gather feedback from testers or potential customers.

Step 7: Build a strong relationship with your manufacturer

Once you’ve found a reliable manufacturer, focus on fostering a long-term partnership.

Tips for maintaining a good relationship:

- Provide clear feedback: Constructive input helps improve future production runs.

- Plan ahead: Give manufacturers sufficient lead time for orders.

- Acknowledge their efforts: Express appreciation to build goodwill and loyalty.

Common challenges and solutions in finding a yoga pants manufacturer

1. Quality inconsistencies

Not all manufacturers deliver consistent quality, especially for bulk orders.

Solution: Implement strict quality control checks and visit the factory if possible.

2. High MOQs

Startups may struggle to meet the minimum order quantities of some manufacturers.

Solution: Look for small-scale manufacturers or negotiate lower MOQs during initial orders.

3. Communication barriers

Language and cultural differences can lead to misunderstandings.

Solution: Use clear, concise language and consider hiring a sourcing agent for overseas suppliers.

The rise of sustainable yoga pants manufacturing

As sustainability becomes a priority for consumers, many brands are opting for eco-friendly options like recycled polyester or organic cotton5.

Sustainable materials:

- Recycled polyester: Made from post-consumer plastic bottles.

- Organic cotton: Grown without harmful pesticides.

- Bamboo blends: Soft, breathable, and biodegradable.

Eco-friendly manufacturers

Look for suppliers who prioritize sustainability through:

- Water-saving dyeing techniques.

- Ethical labor practices.

- Certifications like GRS (Global Recycled Standard) or Fair Trade.

Pro Tip: Highlight your sustainable practices in marketing to attract eco-conscious customers.

Conclusion

Finding a good yoga pants manufacturer requires careful planning, thorough research, and clear communication. By defining your requirements, evaluating potential suppliers, and testing their reliability, you can establish a partnership that supports your brand’s growth. Whether you’re launching a sustainable line or focusing on performance-driven designs, the right manufacturer will help bring your vision to life and ensure success in the competitive activewear market.

-

It helps locate reputable global activewear suppliers for your brand. ↩

-

It provides direct exposure and networking with key industry players. ↩

-

It clarifies cost differences, production timelines, and communication issues. ↩

-

They ensure consistent quality, ethical standards, and safe materials usage. ↩

-

They lower environmental impact, appealing to eco-friendly brand consumers. ↩