Launching a hoodie line is exciting—until you start looking for a manufacturer. Suddenly, you’re faced with endless choices, conflicting claims, and vague promises. It doesn’t have to be this way.

To choose the right custom hoodie manufacturer, evaluate their experience, fabric knowledge, quality control systems, and design support. Look for real references, certifications, and flexible MOQ policies.

I’ve been burned by flashy websites with no substance. That’s why I created this guide—so you can avoid the pitfalls and build your brand with confidence.

What Should You Look for in a Custom Hoodie Manufacturer?

A great-looking hoodie starts with the factory. Your supplier affects your quality, cost, and customer satisfaction.

The best custom hoodie manufacturers1 combine experience, strong QC, high fabric knowledge, and the ability to scale with your brand.

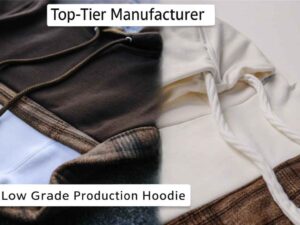

Hoodie Quality Comparison

Hoodie Quality Comparison

✅ Essential Qualities to Expect

- Years of manufacturing experience

- Reliable references or case studies

- ISO, WRAP, or OEKO-TEX certifications

- Transparent pricing & communication

🧵 Fabric, Stitching, and Printing Quality

| Factor | What to Look For |

|---|---|

| Fabric Quality | Dense weave, pre-shrunk, consistent GSM |

| Stitching Quality | Flatlock or coverstitch for durability |

| Print Techniques | Screen, DTG, embroidery, puff, transfer |

Poor stitching or cheap ink can ruin your brand’s reputation. I always request stitch samples and wash tests before placing bulk orders.

💡 Why Quality Impacts Brand Image

- Customers notice fit and finish instantly

- Returns often come from poor feel or shrinkage

- Instagram-worthy details build brand loyalty

I’ve seen brands fail because their hoodies pilled after two washes. Your factory needs to care as much as you do.

How Do Custom Hoodie Manufacturers Handle Small MOQ Orders?

Low MOQs are essential for small brands—but not all factories offer them.

Many custom hoodie manufacturers accept small MOQs today—sometimes as low as 100 pcs—especially in China. Some also offer free or low-cost samples to help you validate designs.

💼 The Challenges of Small-Batch Production

Factories prioritize larger buyers. Small orders may face:

- Slower scheduling

- Limited fabric/color choices

- Higher cost per piece

💸 Cost-Benefit of Low MOQ + Sampling

| Feature | Benefit for Small Brands |

|---|---|

| Small MOQ | Test styles without heavy risk |

| Free Samples | Confirm quality before committing |

| Flexible Styles | Custom details with limited budget |

Look for factories with in-house sampling teams—they can produce hoodie samples in 5–7 days and help you iterate quickly.

Which Materials Are Best for Custom Hoodies?

Material matters. It defines comfort, price, and how your brand is perceived.

Cotton, polyester, fleece, and French terry dominate hoodie production. Cotton feels premium, poly adds durability, and terry is perfect for layering.

🧶 Pros and Cons of Hoodie Materials

| Material | Pros | Cons |

|---|---|---|

| 100% Cotton | Soft, natural, breathable | Can shrink, higher cost |

| Polyester | Strong, wrinkle-resistant | Less breathable, feels synthetic |

| Cotton Fleece | Warm, plush interior | Heavy, not great for summer |

| French Terry | Lightweight, stylish loops | Less warmth, mid-range pricing |

🌱 Trends in Eco-Friendly Hoodie Fabrics

- Recycled polyester blends from bottles

- Organic cotton with GOTS certification

- Bamboo fleece with natural antimicrobial properties

Factories offering eco-certifications and sustainable dyeing can help your brand stand out.

💰 Material Choice Affects Brand and Cost

- Cotton = Premium, classic

- Poly blends = Budget-friendly, performance wear

- Eco fabrics = Sustainability-focused audiences

Your fabric is your first impression—make it count.

Are All Hoodie Manufacturers Capable of Private Label Production?

Not all factories are equipped for full branding. That’s a dealbreaker for growing brands.

Good custom hoodie manufacturers can add logos, woven tags, care labels, and retail-ready packaging to match your brand identity.

🏷️ Private Label vs. White Label

| Label Type | Description | Ideal For |

|---|---|---|

| White Label | Generic design + custom tag/logo | Budget brands, quick launch |

| Private Label | Fully branded + custom design | Established or niche brands |

🧷 Key Branding Options to Expect

- Custom embroidered or printed logos

- Woven neck labels and hang tags

- Branded polybags, gift boxes, or eco-packing

When I started, I underestimated packaging. Now, I know it’s part of the unboxing experience—and your customers notice.

Do Custom Hoodie Manufacturers Offer Free Design Support?

Yes, many modern hoodie manufacturers offer design help—especially helpful for startups.

Some hoodie factories provide free tech packs, mockups, and material suggestions to support smaller brands and designers.

🎨 Why Design Support Matters

- Avoid costly errors from miscommunication

- Accelerate product development cycles

- Improve visual communication with team/stakeholders

🧠 Real Examples from Chinese Factories

| Design Service | Value to You |

|---|---|

| Free 2D Mockups | Visualize final hoodie |

| Tech Pack Templates | Faster factory communication |

| In-House Designers | Tweak fit, graphics, branding |

I’ve saved thousands by using free in-house design help from my factory—it cut back-and-forth in half.

Is It Safe to Work with Overseas Custom Hoodie Manufacturers?

Working with overseas suppliers is safe—if you do it right.

The key is to verify legitimacy, request third-party audits, and insist on clear contracts. Many Chinese manufacturers now offer video calls, certifications, and fast shipping options.

🔍 Common Concerns: Quality, Delay, Communication

- Language barriers = confusion over specs

- Time zones = slower response time

- Shipping delays = affect launch windows

🔐 How to Protect Yourself

- Use contracts with penalties for delays

- Require sample approval before production

- Check audits, factory photos, and references

- Use Alibaba Trade Assurance or Escrow

Trust is earned—start with small orders and grow with the supplier.

How Long Does It Take to Produce Custom Hoodies?

Lead time depends on complexity, fabric, and your factory’s schedule.

Sample development usually takes 5–10 days. Bulk production takes 15–30 days. Shipping adds 7–20 days depending on your region.

🗓️ Typical Hoodie Production Timeline

| Phase | Duration |

|---|---|

| Design Finalization | 3–5 days |

| Sample Development | 5–10 days |

| Bulk Production | 15–30 days |

| Shipping (Sea/Air) | 7–20 days |

⏱️ Factors That Affect Production Time

- Fabric in stock vs. dyed-to-order

- Order quantity (100 pcs vs. 5,000 pcs)

- Custom details (e.g., embroidery, zipper type)

- Factory load (peak seasons = delays)

⚡ Tips to Speed Up Production

- Finalize tech packs early

- Choose stock fabrics/colors

- Approve samples fast via video/photos

- Use a factory with strong logistics partners

Fast isn’t always better—but reliable is. Align timelines with your marketing calendar to avoid launch-day stress.

Conclusion

Choosing the right custom hoodie manufacturer is about more than price. It’s about trust, communication, quality, and long-term fit. With the right partner, you’re not just producing hoodies—you’re building your brand, one stitch at a time.

-

Explore this link to find top-rated manufacturers that cater specifically to startups, ensuring quality and support for your brand. ↩