Clothing decoration is not only a key component of the fashion industry, but also an important means of cultural expression and personality display. It uses different technologies and materials to enhance the beauty and uniqueness of clothing, thereby satisfying people’s pursuit of aesthetics and personalization. Among the many clothing decoration techniques, embroidery and screen printing are two of the most popular and time-honored methods.

Embroidery, as an ancient handicraft, uses needle and thread to create patterns or words on cloth, giving clothing a sophisticated and traditional beauty. Its diverse techniques and fineness make each embroidery work unique and rich in artistic value. From fine hand embroidery to modern machine embroidery, the adaptability and flexibility of this technique have given it a place in every style of clothing design.

Screen printing is a more modern technology that creates a template on a screen and then transfers ink or other types of printing materials to the fabric through the template. This method is suitable for mass production and can produce complex multi-color patterns quickly and economically. Screen printing is highly adaptable and efficient, making it an integral part of the contemporary fashion industry.

In general, embroidery and screen printing are two main technologies for clothing decoration, each with its own characteristics. They not only improve the aesthetics of clothing, but also enrich the cultural connotation and expression of clothing.

Thread and printing ink: a wonderful dialogue between embroidery and screen printing in clothing art

The article aims to provide an in-depth comparison and analysis of two major garment decoration techniques: embroidery and screen printing. We’ll explore the unique characteristics, application scenarios, and importance of these two technologies in modern clothing design. By comparing the differences between the two technologies in terms of material use, design complexity, production costs, durability and market acceptance, we aim to provide a comprehensive perspective to help designers, manufacturers and fashion enthusiasts better Understand the advantages and limitations of each technology.

In addition, the article will discuss how embroidery and screen printing adapt to changes in the contemporary fashion world and their potential development directions in future clothing design. Through this article, readers will gain in-depth insights into how to select appropriate embellishment techniques to enhance the aesthetics and market appeal of garment designs.

Embroidery Technology

Embroidery, as an ancient and exquisite handicraft technology, has a long and rich history. It originated in prehistoric times when people used bone needles and animal tendon threads to decorate patterns on leather. Over time, embroidery techniques developed and spread across the globe, with each culture adding unique styles and techniques to it.

In China, embroidery is considered an elegant art form that dates back to at least the Han Dynasty. Known for its fine craftsmanship and rich colors, Chinese embroidery became an important part of royal and aristocratic costumes.

In medieval Europe, embroidery became an important way to express religious and aristocratic symbols, especially on church vestments and royal emblems. By the Renaissance, embroidery became a symbol of fashion and was widely used in everyday clothing and home decorations.

With the advent of the Industrial Revolution, embroidery began to shift from handicrafts to mechanized production. The invention of the first embroidery machine at the end of the 19th century marked the beginning of this transformation, making embroidery production more efficient and economical.

In the 20th century, with the further development of technology, the emergence of computerized embroidery machines allowed complex designs to be copied quickly and accurately, greatly improving the production efficiency and design diversity of embroidery.

Today, embroidery remains a highly appreciated decorative art that has not only retained its traditional and cultural value but also plays an important role in the modern fashion world. From haute couture to everyday casual wear, embroidery attracts designers and consumers with its unique aesthetic and sophistication. At the same time, with the rise of sustainable fashion, hand embroidery, as a traditional skill, is receiving more and more attention and is regarded as an important way to maintain cultural heritage and promote environmentally friendly production methods.

The allure of embroidery art: discover its diverse techniques and infinite applications

The types and characteristics of embroidery technology are extremely rich, and each technology has its own unique aesthetic characteristics and application scenarios. Here are some of the main embroidery techniques and their characteristics:

Surface Embroidery:

- Features: Performed on the surface of the fabric, using various stitches and threads, such as cotton, silk or metal threads.

- Application: Widely used in fashion apparel, home decorations (such as pillows, sheets) and handicrafts.

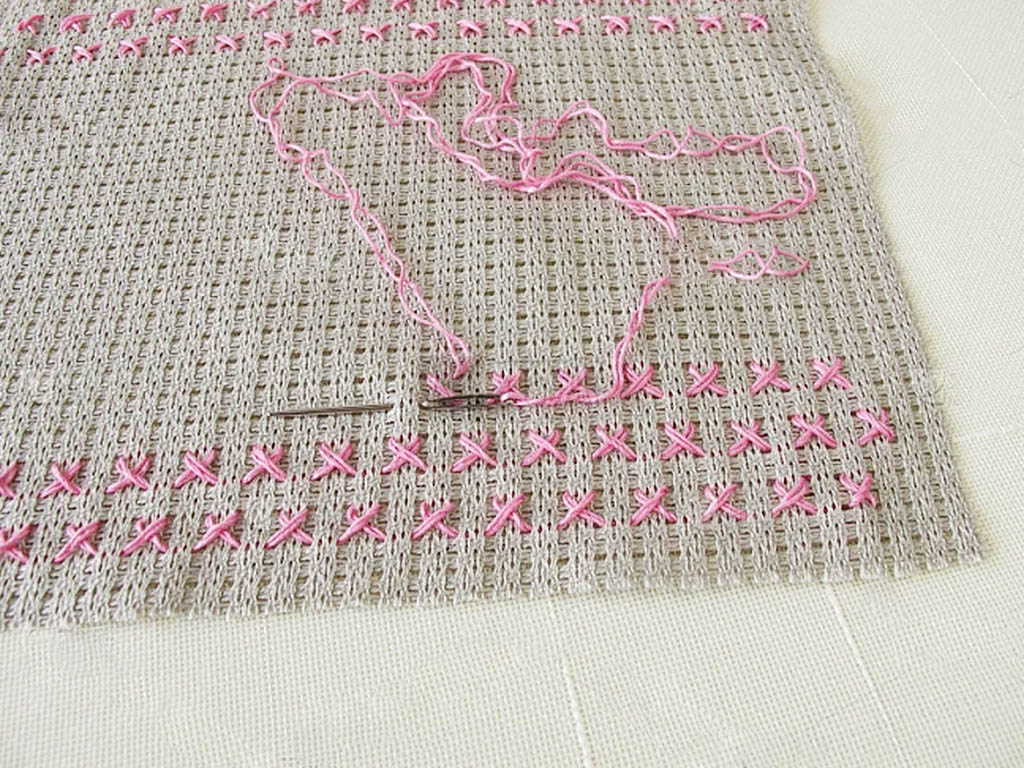

Cross Stitch:

- Features: Made by cross stitching that creates an “X” shape on the fabric, suitable for creating precise patterns.

- Application: Popular in home crafts and folk art, used to decorate tapestries, tablecloths and clothing.

Whitework Embroidery:

- Characteristics: Typically embroidered on white cloth using white thread, emphasizing the nuances of texture and pattern.

- Application: Traditionally used for wedding and religious wear, as well as high-end home textile products.

Goldwork embroidery:

- Features: Made with gold, silver or other metal threads to create a gorgeous, shiny effect.

- Application: Commonly used in military uniforms, religious clothing and luxury fashion.

Needle Lace:

- Features: Creates delicate lace-like patterns that emphasize perspective and detail.

- Application: Suitable for decoration of wedding dresses, evening gowns and high fashion.

Machine Embroidery:

- Features: Using machine-automated production, complex patterns can be copied quickly.

- Applications: For mass production of apparel, hats, bags and promotional items.

3D Embroidery:

- Features: Create three-dimensional effects through stacking and layering techniques.

- Application: Popular in fashion accessories, artwork and creative designs.

Each embroidery technology has its own unique charm and applicable fields. From traditional handicrafts to modern mechanized production, embroidery continues to evolve, adding unlimited creativity and beauty to clothing and decorations.

The double-sided mirror of embroidery art: Exploring its elegant beauty and practical limitations

Embroidery technology, as an ancient and widely used method of clothing decoration, has unique advantages and some limitations.

Advantages of embroidery technology

- Aesthetic value: Embroidery provides rich texture and depth, which can create unique visual effects and add to the artistic beauty of clothing.

- Personalization and Uniqueness: Embroidery is customizable and each piece can be unique, perfect for personalized designs.

- Durability: Compared to other printing techniques, embroidery is more durable and less likely to fade or fray, especially when high-quality threads are used.

- Tradition and cultural inheritance: Embroidery is often associated with the traditions of a specific culture. It is not only a decorative technique, but also a part of cultural heritage.

- Variety: The variety of embroidery techniques makes it suitable for a variety of styles and materials, from delicate silks to rough canvases.

Limitations of embroidery technology

- Higher cost: Especially fine hand embroidery requires a lot of time and skills, so the cost is relatively high.

- Low production efficiency: Compared with mechanized printing, embroidery (especially hand embroidery) is produced slowly.

- Design Complexity Limitations: Certain extremely intricate or minute details may be difficult to accurately represent through embroidery.

- Fabric limitations: Not all types of fabrics are suitable for embroidery, especially very thin or very thick fabrics may not be suitable.

- Weight and Comfort: In some cases, embroidery may add weight to the garment and may affect comfort, especially within the embroidered areas.

In summary, although embroidery technology has significant advantages in aesthetics and personalization, it has limitations in terms of cost, efficiency and certain designs. Understanding these pros and cons is crucial for costume designers when choosing embellishment techniques.

Screen Printing Technology

Screen printing is a popular printing technology that is widely used to print patterns on clothing and other products. Its basic principle is to use the silk screen as a printing template, transfer ink through the mesh, and print patterns onto the material surface. Here is an overview of the basic principles and historical background of screen printing:

Fundamental

At its core, screen printing is a taut mesh, usually made of silk, nylon, or other synthetic materials. This grid is fixed to a frame to form a “screen”. The parts of the pattern that are to be printed are transparent on the grid, while the parts that do not need to be printed are covered with an ink-impermeable material to form a barrier. During the printing process, ink is placed on top of the screen and a squeegee (or squeegee) is used to press evenly across the screen, causing the ink to transfer through the transparent portion to the material below.

History background

The history of screen printing can be traced back to China about 1,000 years ago, where it was originally used to decorate fabrics and paper. This technique later spread to other Asian countries, such as Japan, where more sophisticated screen printing methods were developed. In the 18th century, this technology was introduced to Europe with the silk trade, but it was not until the early 20th century that it began to be widely used in industrial production. Especially in the mid-20th century, with the introduction of synthetic materials and the development of photographic platemaking technology, screen printing technology was significantly improved, making it more suitable for commercial and artistic applications.

In modern times, screen printing is widely used in clothing design, poster production, art, and industrial products due to its versatility, durability, and bright colors. Although the rise of digital printing technology has provided new options, screen printing remains an irreplaceable choice in many applications, especially where high durability and printing on specialty materials are required. For high-quality screen printing services, consider partnering with ModaKnits, a leader in fashion decoration techniques.

Screen printing: from classic craftsmanship to modern art, its multi-faceted charm

Screen printing is a versatile and widely used printing technique with a wide range of processes, variations and specialties. Here is a detailed explanation:

Screen printing process

- Design production: You first need a print design, which is usually a digital image or hand-drawn pattern.

- Screen preparation: Choose a suitable screen screen and adjust the fineness of the grid according to printing needs.

- Apply photosensitive glue: Apply a layer of photosensitive glue evenly on the screen.

- Exposure: The design is placed on the screen and exposed to strong light. The portion of photoresist not covered by the design will harden.

- Rinse: After exposure, rinse the screen with water. The unhardened photosensitive adhesive will be washed away, leaving a blank part of the printed pattern.

- Printing: Place the screen on the object to be printed, pour ink, and use a scraper to scrape and press evenly to transfer the ink to the surface of the object through the mesh.

- Drying: Finally, the printed matter is dried to fix the pattern.

Screen printing variations

- Multi-color printing: By using multiple screens, each representing a color, complex multi-color designs can be created.

- Three-dimensional screen printing: increasing the thickness of the ink layer to create a print with a three-dimensional effect.

- Photographic Screen Printing: Using photographic technology to create screens that can accurately reproduce complex images and details.

Characteristics of screen printing

- Wide applicability: Can print on a variety of materials, including paper, cloth, wood, glass and metal.

- Strong durability: Screen printing ink has strong coverage, and the printing effect is durable and colorful.

- High degree of freedom: can handle objects of various sizes and shapes, suitable for various custom designs.

- Cost-effective: For high-volume production, screen printing is a cost-effective option.

Screen printing is very popular in both art and industry due to its versatility and adaptability. Whether it is a simple single color pattern or a complex multi-color design, screen printing has its own unique way of delivering outstanding results.

Screen printing: the colorful and versatile art of printing

Screen printing is a popular printing technology that plays an important role in the design of clothing and other products. The following is an analysis of its advantages and disadvantages:

Advantages of screen printing

- Multi-material applicability: Can print on a variety of materials, including cloth, paper, wood, plastic, glass, etc.

- Durability: The printed pattern is resistant to washing and wear, and is especially suitable for products that require long-term use.

- Vibrant colors: Screen printing can produce high-saturation, bright-color effects, which is especially suitable for large-area solid color printing.

- Cost-Effectiveness: When mass-produced, the cost per piece is relatively low.

- Adaptability: Can be used on items of different shapes and sizes, very flexible.

- Pattern Diversity: Ability to achieve complex patterns and fine details.

Disadvantages of screen printing

- Initial Investment Cost: There are some initial costs involved in setting up screen printing, especially when making screens and stencils.

- Production speed: Compared to other modern printing technologies, screen printing can be more time-consuming, especially in multi-color printing processes.

- Design Limitations: Some extremely detailed or complex patterns may be difficult to accurately achieve with screen printing.

- Cleaning and Maintenance: Screens require regular cleaning and maintenance to maintain printing quality.

- Environmental Impact: Some inks and cleaners used may be harmful to the environment.

In summary, screen printing is widely used due to its advantages in multi-material applicability, durability and vivid colors, but it also has certain limitations, such as cost, speed and environmental impact. Understanding these advantages and disadvantages can help make appropriate choices in different application scenarios.

Embroidery and screen printing: a textural showdown of decorative techniques

Embroidery and screen printing are two different decorative techniques with significant differences in texture, durability, cost, production speed and design flexibility:

Texture:

- Embroidery: Embroidery techniques often provide a richer texture because the threads create raised and raised patterns in the fabric, adding a tactile layering.

- Screen printing: The texture of screen printing is relatively flat. The printing ink is on the surface of the material, and there is usually no uneven feeling.

Durability:

- Embroidery: Embroidery is usually highly durable, with the threads firmly anchored to the fabric and not prone to fading or fraying.

- Screen printing: Although durable, printing may gradually lose color and texture after prolonged use and multiple washes.

cost:

- Embroidery: Embroidery generally requires more hand labor and time and therefore costs more, especially for intricate designs.

- Screen printing: When producing in large quantities, screen printing can be more cost-effective, with a lower cost per piece.

Production speed:

- Embroidery: Embroidery usually takes more time because each design needs to be made and embroidered individually.

- Screen printing: Screen printing produces faster in mass production and is suitable for large-scale manufacturing.

Design flexibility:

- Embroidery: Embroidery has certain design limitations, especially with complex patterns and details, and making and adjusting the screen can be more time-consuming.

- Screen printing: Screen printing is relatively flexible in design, can quickly produce screen templates, and is suitable for a variety of colors and patterns.

To sum up, embroidery and screen printing each have their own advantages and limitations, and which technique to choose depends on the requirements and goals of the project. Embroidery is suitable for designs that focus on texture and high durability, while screen printing is more suitable for large-volume, colorful and diverse printing needs.

Embroidery and screen printing: market options for different decorative techniques

Embroidery and screen printing are two different decorative techniques, and they have some differences in suitable clothing styles and market positioning:

Clothing style and market positioning suitable for embroidery

- High-End Clothing: Embroidery is often seen as an exquisite decorative technique suitable for high-end and luxurious clothing styles. It can add texture and uniqueness to clothing, making it attractive in the high-end market.

- Traditional style: Embroidery is often combined with traditional style clothing, such as ethnic clothing, wedding dresses, formal wear, etc. It can add traditional and cultural elements to clothing.

- High durability requirements: Due to the high durability of embroidery, it is suitable for clothing that requires long-term use and frequent cleaning, such as work uniforms, sports team uniforms, etc.

- Unique Designs: Embroidery is suitable for unique design needs, especially those garments that require intricate patterns and details.

Apparel styles and market positioning suitable for screen printing

- Casual and fashionable: Screen printing is often used for casual and fashionable clothing because it can easily achieve colorful and diverse patterns and designs to adapt to different fashion trends.

- Mass production: Screen printing is very efficient in mass production and is suitable for high-volume garment manufacturing, such as T-shirts, sportswear, etc.

- Fast fashion: Fast fashion brands often use screen printing because it can quickly respond to market demand and produce various patterns and prints.

- Pattern diversity: Screen printing is suitable for garments that require a variety of colors and patterns, and complex design requirements can be achieved.

To sum up, embroidery and screen printing each have unique advantages in clothing style and market positioning. Embroidery is suitable for high-end, traditional and markets that require high durability, while screen printing is suitable for casual, fashion, fast fashion and mass-produced markets. Choosing the right decoration technology depends on the brand’s positioning and target market.

Embroidery and screen printing : future innovations in fashion decoration

Embroidery and screen printing technologies are constantly developing and innovating, and there are many potential development directions and innovation possibilities in the future:

The future development direction and innovation possibilities of embroidery technology:

- Smart embroidery: In the future, embroidery technology may be integrated with smart technology to create smart embroidery that can sense and respond to the environment. These smart embroideries could be used in areas such as wearable technology, healthcare and sports monitoring.

- Sustainability: Embroidery materials and processes may become more sustainable, using eco-friendly threads and materials to reduce environmental impact.

- 3D embroidery: Embroidery technology may be further developed to achieve three-dimensional 3D embroidery effects, increasing texture and visual appeal.

- Automation and machine learning: Automated machines and machine learning algorithms can be used to speed up embroidery production and improve accuracy, reducing manual intervention.

- Material innovation: New embroidery materials and threads may drive innovation in embroidery design, creating more diverse patterns and effects.

The future development direction and innovation possibilities of screen printing technology:

- Smart fibers and materials: Screen printing technology may be combined with smart fibers and materials to create garments with temperature-regulating, light-sensitive or other smart features.

- Digital printing: Digital screen printing technology may evolve to enable higher printing resolution and precision to create more complex patterns.

- Customizability: Screen printing can further promote the development of customizable clothing, allowing consumers to personalize their clothing.

- Biodegradable ink: Using biodegradable printing ink can reduce environmental impact and is in line with the trend of sustainability.

- Nanotechnology: Nanotechnology may be applied to screen printing to improve printing effects and material properties.

In general, the future development direction of embroidery and screen printing technology includes areas such as intelligence, sustainability, material innovation, automation and digitalization. These innovations will promote these two technologies to play a greater role in clothing manufacturing and decoration and meet changing market needs.

Embroidery vs. Screen Printing: Which Technology Is Better for Your Apparel Needs?

Embroidery and screen printing technologies each have their own specific needs and market trends:

Embroidery technology is more suitable for:

- High-end market: Embroidery technology performs well in the high-end market and can add luxury and texture to products.

- Traditional Style: For traditional style clothing, embroidery is an ideal way to embellish and incorporate cultural elements.

- High durability requirements: Clothing that requires long-term use and frequent cleaning, such as work uniforms and sports team uniforms, can choose embroidery.

- Unique Designs: Embroidery is suitable for garment designs that require unique, intricate patterns and details.

Screen printing technology is more suitable for:

- Fast fashion market: Screen printing is very efficient in the fast fashion market, suitable for mass production and quick response to market demand.

- Colorful and diverse patterns: Screen printing can achieve a variety of colors and patterns to adapt to different fashion trends and consumer tastes.

- Casual and fashionable clothing: For casual and fashionable clothing, screen printing can create diverse designs to meet the needs of young fashion consumers.

- Customizability: Screen printing facilitates the creation of customizable garments, allowing consumers to personalize their garments.

Overall, choosing embroidery or screen printing technology depends on the brand’s positioning, product type and target market. Both technologies have their own unique advantages, and the most appropriate decoration method can be selected based on specific needs and market trends.

=============================================

Finally, I want to share my experience with ModaKnits! I was looking for an excellent partner in the field of fashion decoration, and ModaKnits was exactly what I needed. Not only are they proficient in embroidery techniques, they also have expertise in screen printing techniques. Every moment I work with them is filled with creativity and passion.

ModaKnits stands out for its technical excellence and their team is not only skilled in various decorative techniques but also able to transform my ideas into unique designs. Their expertise and high-quality finishing grace my products, and my customers rave about it.

ModaKnits is not only my partner, but also my fashion choice. I am proud of their work and I highly recommend ModaKnits to anyone in need of stylish decorating services!