Acetate fabric is a semi-synthetic material known for its silk-like sheen, softness, and excellent drape. Originally developed as an affordable alternative to silk, it has gained popularity in both fashion and home textiles. Its lightweight nature, versatility, and smooth texture make it a staple in elegant garments like evening dresses, scarves, and linings.

In this blog, we explore the unique qualities of acetate fabric, its wide-ranging applications, and its environmental considerations.

What is Acetate Fabric?

Acetate fabric is a semi-synthetic textile created from cellulose found in wood pulp or cotton linters. Known for its luxurious, silky texture, acetate is commonly used in fashion for its smooth finish and elegant drape. Often compared to silk, acetate fabric offers a cost-effective yet visually appealing alternative, making it a popular choice in the production of formalwear and linings.

Origin and Source of Acetate Fibers

Acetate fibers originated in the early 20th century as a solution to the high costs associated with silk. Derived from cellulose, the production process involves chemically treating the cellulose with acetic acid, which results in a fiber that can be spun into yarn and then woven into fabric. These fibers are known for their ability to hold vibrant colors and maintain a silky texture, providing the same aesthetic qualities as more expensive textiles like silk.

Historical Significance and Modern Usage

Historically, acetate fabric was developed to meet the growing demand for affordable luxury textiles. Since its inception, it has become a staple in the fashion industry, replacing silk in many applications due to its affordability and similar visual properties. Today, acetate is used in evening gowns, blouses, and linings, offering a lightweight, breathable material that drapes well and feels soft against the skin.

Acetate Fabric Today

In modern fashion, acetate fabric continues to be valued for its affordability and elegance. It is widely used in both high-end and everyday clothing, particularly in garments that require a soft, flowy appearance, such as dresses and blouses. At Modaknits, we focus on sourcing premium acetate fabrics that balance luxury with practicality, ensuring our garments are both beautiful and functional for contemporary consumers.

What Makes Acetate Fabric Unique?

Acetate fabric is recognized for its luxurious qualities, often used as a cost-effective alternative to silk. Its combination of elegant appearance, softness, and practical performance makes it a highly valued textile across the fashion industry.

Key Characteristics and Qualities

- Silk-like Sheen and Softness: Acetate fabric has a smooth, shiny surface that closely mimics the look and feel of silk. This characteristic gives garments made from acetate a high-end, luxurious appearance at a lower cost.

- Drape and Flow: Acetate’s excellent drape makes it a perfect choice for garments that need to flow and move elegantly, such as evening gowns, scarves, and blouses. Its fluidity adds sophistication to fashion designs.

- Color Fastness: Acetate holds dyes exceptionally well, allowing for vibrant and bold colors that resist fading over time. This quality makes it a favorite for fashion designers seeking to create striking, colorful pieces.

- Low Static: Unlike other synthetic fibers, acetate generates less static electricity, making it more comfortable to wear in a variety of climates. This property enhances its wearability, especially for formal or evening attire.

Comparison with Other Fabrics

- Acetate vs. Silk: Both acetate and silk offer a similar luxurious sheen and softness. However, acetate is more affordable and easier to care for, while silk is more delicate and expensive, requiring special handling.

- Acetate vs. Polyester: Polyester is more durable and resistant to wrinkling compared to acetate. However, acetate excels in terms of softness, sheen, and drapability, making it a better option for garments that aim to replicate the elegance of silk.

- Acetate vs. Rayon: Both acetate and rayon are semi-synthetic fibers derived from cellulose, but acetate has a silkier texture and better drape, while rayon is more breathable and absorbent. This makes acetate ideal for formalwear, while rayon is preferred for casual and breathable summer clothing.

Acetate fabric’s combination of affordability, silk-like qualities, and practical properties makes it a versatile choice in both fashion and textile manufacturing.

How is Acetate Fabric Made?

Acetate fabric is produced through a series of chemical processes that convert natural cellulose, primarily from wood pulp or cotton linters, into fibers. The end result is a luxurious fabric known for its sheen, softness, and silk-like qualities.

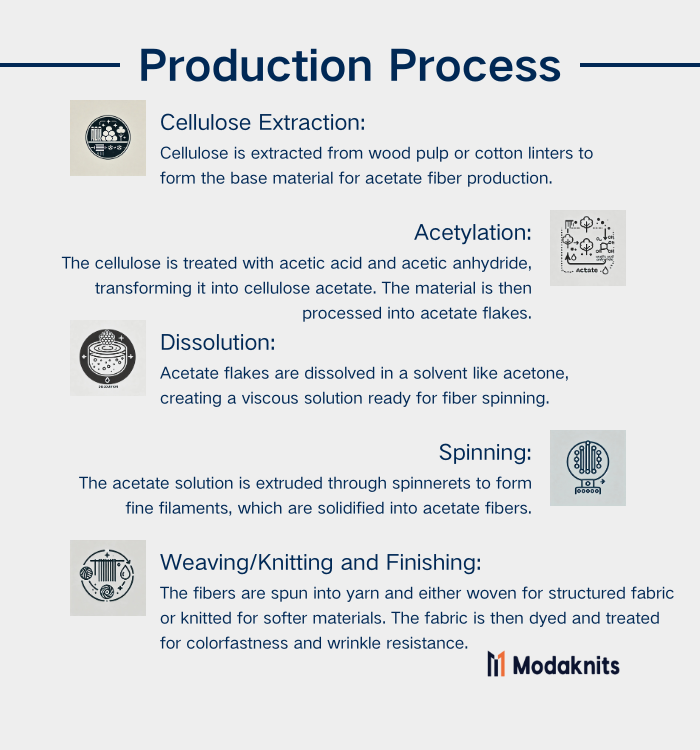

Production Process

- Cellulose Extraction: The process begins by extracting cellulose from wood pulp or cotton linters. This natural material serves as the foundation for acetate fiber production.

- Acetylation: In this stage, the extracted cellulose is treated with acetic acid and acetic anhydride. This acetylation process transforms the cellulose into cellulose acetate, which is the primary component of acetate fabric. The resulting material is then processed into small flakes, known as acetate flakes.

- Dissolution: The acetate flakes are dissolved in a solvent, such as acetone, to create a viscous solution. This step prepares the material for spinning into fibers.

- Spinning: The acetate solution is extruded through spinnerets, devices with tiny holes, to form fine filaments. These filaments are solidified through evaporation or immersion in a chemical bath, resulting in the creation of acetate fibers.

- Weaving or Knitting: The acetate fibers are spun into yarn, which is then woven or knitted into fabric, depending on the intended use. Woven acetate fabric offers structure and is used in formalwear, while knitted fabric provides softness and flexibility, ideal for more casual garments.

- Finishing: In the final stage, the acetate fabric undergoes dyeing and finishing treatments to enhance its appearance, texture, and durability. These treatments often focus on improving the fabric’s colorfastness and ability to resist wrinkling.

Regions Known for Acetate Fabric Production

- United States: Known for producing high-quality acetate fabrics, the U.S. plays a key role in luxury fashion and formalwear markets.

- China: A major global producer, China manufactures a wide range of acetate fabrics at competitive prices for both domestic and international markets.

- Japan: Recognized for producing premium acetate fabrics with exceptional quality, particularly in high-end fashion.

Acetate fabric’s silk-like appearance, drape, and affordability make it popular in both luxury fashion and everyday garments, contributing to its wide use in the textile industry.

What Are the Types of Acetate Fabric?

Acetate fabric is available in several variations, each offering distinct qualities suited to different textile and fashion applications:

- Plain Acetate: This is the most common form of acetate fabric, known for its smooth texture, luxurious sheen, and excellent draping quality. Plain acetate is frequently used in linings, formalwear, and evening gowns where its elegance and flowy characteristics enhance the garment’s overall appeal.

- Textured Acetate: Featuring a crinkled or textured finish, this type of acetate adds visual interest and depth to garments. It is often used in fashion pieces like dresses, skirts, and blouses, where a more structured or unique surface is desired.

- Blended Acetate: Acetate can be blended with other fibers such as silk, wool, or polyester to enhance its durability, flexibility, and resistance to wrinkling. Blended acetate fabrics are ideal for everyday wear like skirts, dresses, and tops, combining softness with practicality.

- Triacetate: A more chemically processed form of acetate, triacetate fabric is highly resistant to wrinkles, shrinkage, and heat, making it perfect for garments that require easy care and long-lasting wear. Triacetate is often used in sportswear, pleated skirts, and home textiles such as drapes due to its durability.

Each type of acetate fabric offers different properties, allowing designers and manufacturers to select the right variation for specific purposes, from luxury fashion items to practical, easy-care clothing.

How is Acetate Fabric Used in Textiles?

Acetate fabric is widely recognized for its versatility and luxurious sheen, making it a popular choice across various fashion and home textile applications. Below are some common uses of acetate fabric:

- Evening Wear and Gowns: Acetate’s silky, lustrous appearance and excellent drape make it an ideal fabric for formal attire such as evening dresses, gowns, and wedding dresses. Its ability to mimic the flow and feel of silk makes it a cost-effective option in luxury fashion.

- Blouses and Scarves: Acetate is lightweight and soft, which makes it perfect for creating delicate garments like blouses, scarves, and shawls. The fabric’s smooth texture and rich color retention enhance the overall aesthetic of these items, adding elegance to casual and formal outfits.

- Linings for Jackets and Coats: Acetate is commonly used as a lining material for jackets, coats, and suits. Its smooth surface allows garments to glide easily over the body and other clothing layers, improving comfort while maintaining a polished look.

- Home Textiles: Acetate’s sheen and drape are also valuable in home décor applications, such as curtains, upholstery, and bed linens. The fabric’s ability to hold vibrant colors adds a luxurious feel to home interiors while remaining durable and easy to care for.

- Ties and Accessories: The luxurious sheen and softness of acetate make it suitable for creating high-end accessories like ties, pocket squares, and hair bands. These items benefit from the fabric’s elegant finish and comfort.

Acetate fabric’s balance of affordability, elegance, and functionality ensures its continued popularity in both fashion and home textile industries.

How Much Does Acetate Fabric Cost?

Acetate fabric prices vary depending on factors such as quality, type, and production location. Understanding these differences can help manufacturers make informed sourcing decisions for their collections.

Acetate Fabric Costs in the United States

- Basic Acetate Fabric: In the U.S., basic acetate fabric typically costs between $6 and $12 per yard. This type is commonly used for linings, lightweight fashion garments, and casual wear due to its affordability.

- Premium Acetate Fabric: Higher-quality acetate fabrics, including blends or those with special finishes, can cost between $12 and $25 per yard. These premium varieties offer luxurious qualities, such as a silk-like feel, making them suitable for high-end eveningwear and formal garments.

Acetate Fabric Costs in China

- Basic Acetate Fabric: In China, the cost of basic acetate fabric is more competitive, typically ranging from $3 to $8 per yard. The lower production costs in China make it an ideal sourcing destination for budget-conscious manufacturers.

- Premium Acetate Fabric: For higher-end acetate fabrics, including those blended with fibers like silk or polyester, the price in China ranges from $8 to $15 per yard. These blends offer enhanced performance and durability at a lower cost than U.S. equivalents.

Factors Influencing Acetate Fabric Prices

- Blended Acetate: The cost of acetate increases when it is blended with other fibers, such as silk or polyester. These blends add specific performance traits, like improved durability or enhanced drape, which justify the higher price.

- Production Location: Prices are generally lower in regions like China, where manufacturing and labor costs are reduced. In contrast, fabrics produced in the U.S. may be priced higher due to stricter labor standards and production costs.

- Certifications and Quality: Acetate fabrics that carry certifications, such as OEKO-TEX®, may have higher prices due to the environmentally friendly and safe production practices required to obtain such certifications.

Comparing Acetate Fabric Prices: U.S. vs. China

Acetate fabric prices in China are typically 20% to 40% lower than those in the United States. This is largely due to lower labor and production costs, making China a popular option for manufacturers seeking to balance quality with cost efficiency.

By sourcing competitively priced acetate fabrics, Modaknits ensures that it can deliver garments that are both luxurious and affordable, appealing to fashion-conscious and budget-conscious consumers alike.

How Does Acetate Fabric Impact the Environment?

The environmental impact of acetate fabric involves a balance of positive and negative factors, largely influenced by its production processes. Here’s a closer look at the fabric’s sustainability profile:

Positive Environmental Impacts

- Biodegradable: Acetate is a semi-synthetic fiber derived from natural cellulose (usually from wood pulp), making it biodegradable under certain conditions. Unlike purely synthetic fibers, acetate can break down over time, reducing its long-term impact on the environment when disposed of correctly.

- Renewable Resource: The cellulose used to make acetate is sourced from renewable materials like wood pulp, often from fast-growing trees. This makes it a more sustainable choice compared to fully synthetic fibers that rely on non-renewable resources like petroleum.

Negative Environmental Impacts

- Chemical Processing: One of the major environmental downsides of acetate production is the reliance on chemicals such as acetic acid and acetone during the acetylation process. Improper disposal or management of these chemicals can lead to environmental pollution, including water contamination and hazardous waste.

- Water and Energy Usage: Acetate production can be water-intensive, especially during the processing and dyeing stages. Managing wastewater and reducing energy consumption is crucial for minimizing the environmental impact. If not handled properly, the water used in the production process can cause pollution, affecting ecosystems and water quality.

Sustainable Practices

- Certifications: Acetate fabrics that meet certifications such as OEKO-TEX® and the Global Organic Textile Standard (GOTS) ensure that they are produced under strict environmental and social standards. These certifications can guarantee responsible chemical management and sustainable production methods.

- Water Management: Efficient water management systems, such as closed-loop processes, can reduce the environmental toll of acetate production. Proper wastewater treatment helps prevent contamination of local water supplies, further mitigating the negative environmental impact.

While acetate fabric offers eco-friendly benefits like biodegradability and renewable sourcing, its environmental impact depends heavily on the chemicals and water used in production. Sustainable practices and certifications can help improve its overall environmental profile.

Ensuring Acetate Fabric Quality and Certification

At Modaknits, we maintain the highest standards of quality and sustainability for our acetate fabrics through adherence to globally recognized certifications and strict production processes.

Key Quality Indicators

- Fiber Strength and Durability: Acetate fabric is known for its luxurious feel and elegant drape. At Modaknits, we carefully source high-quality fibers to ensure that our acetate garments retain their strength and structure, even with regular use.

- Breathability and Comfort: Acetate is prized for its softness and comfort. Our production processes emphasize maintaining the breathability of the fabric, making it suitable for both casual wear and formal attire.

- Color Retention: One of acetate’s standout qualities is its ability to hold vibrant colors. Modaknits ensures that our acetate fabrics retain their rich, bold hues over time, providing long-lasting visual appeal.

Certifications and Sustainability

- OEKO-TEX® Standard 100: Our acetate fabrics are OEKO-TEX® Standard 100 certified, meaning they are free from harmful chemicals and safe for direct skin contact. This certification gives our customers the confidence that their garments meet strict safety and environmental guidelines.

- ISO Standards: We adhere to ISO standards for quality management and environmental responsibility, ensuring that our production processes are sustainable and consistently meet global benchmarks for excellence.

By prioritizing these certifications and maintaining rigorous quality control, Modaknits guarantees that our acetate garments not only embody luxury and comfort but also align with the growing demand for sustainable fashion.

For more information about our fabrics or to explore our product catalog, please contact us.