Neoprene fabric, also known as polychloroprene, is a versatile synthetic material originally developed in the 1930s as an oil-resistant alternative to rubber.

It is widely recognized for its flexibility, insulation properties, and durability, making it a staple in various industries, particularly in fashion, sportswear, and protective gear.

In this blog, we delve into what makes neoprene fabric unique, its manufacturing process, types, applications, cost factors, environmental impact, and quality certifications.

What is Neoprene Fabric?

Neoprene fabric is a versatile synthetic rubber material created from the polymerization of chloroprene. Known for its excellent resistance to water, heat, and chemicals, neoprene is widely used in applications ranging from wetsuits and activewear to industrial products and accessories. Its flexibility, thermal insulation, and cushioning properties make it ideal for outdoor gear, protective equipment, and fashion garments.

Origin and Production of Neoprene Fabric

Neoprene was first developed in 1930 by DuPont as a more durable and versatile alternative to natural rubber. The production process involves polymerizing chloroprene monomers to form polychloroprene, which is then expanded into sheets or molded into various shapes. The fabric is often laminated onto other textiles to enhance its strength, flexibility, and functionality for specific applications.

Historical Significance and Modern Usage

Initially used in industrial settings, neoprene became a crucial material for protective clothing, particularly in wetsuits, due to its insulating properties. Over time, its usage expanded into sportswear, medical products, and fashion as demand grew for materials that offer flexibility and resistance to harsh conditions. Neoprene’s adaptability to various forms and thicknesses allowed for innovation across different industries, from diving equipment to athletic accessories.

Neoprene Fabric Today

Today, neoprene continues to be an essential material in performance gear and fashion. Its ability to provide warmth, flexibility, and protection against elements has made it popular in activewear, shoes, and accessories. At Modaknits, we source premium neoprene fabric to craft garments that combine style with functionality, ensuring durability and comfort for outdoor enthusiasts and athletes.

What Makes Neoprene Fabric Unique?

Neoprene fabric is renowned for its combination of water resistance, flexibility, and thermal insulation, making it an essential material in a variety of industries, particularly in sports and outdoor wear. Below are the key characteristics and qualities that distinguish neoprene fabric:

Key Characteristics and Qualities

- Water Resistance: Neoprene’s most prominent feature is its water resistance, which makes it the go-to material for wetsuits, diving suits, and other water-related sports gear. It effectively keeps the body dry while providing a protective barrier against water.

- Thermal Insulation: Neoprene offers excellent thermal insulation, retaining body heat in cold environments. This quality is vital for underwater and winter sports equipment, as it helps maintain body temperature even in icy conditions.

- Flexibility and Stretch: Neoprene fabric is highly flexible and stretches easily, which allows for a full range of motion. This makes it perfect for athletic apparel and sportswear, ensuring comfort and mobility for athletes and outdoor enthusiasts.

- Durability: Neoprene is resistant to abrasions, sunlight, and chemical damage, which makes it suitable for long-term use in demanding environments. Its durability ensures that products made from it can withstand harsh conditions without degrading.

- Lightweight: Despite its insulating and protective properties, neoprene remains lightweight, allowing for ease of movement. This balance of protection and mobility makes it ideal for performance and activewear where weight is a concern.

Comparison with Other Fabrics

- Neoprene vs. Rubber: While both are synthetic and provide insulation, neoprene is more flexible and lighter than traditional rubber, making it more comfortable for wearables like wetsuits and outerwear.

- Neoprene vs. Polyester: Polyester is lightweight and quick-drying, but it lacks the insulating properties of neoprene. Neoprene provides both thermal retention and flexibility, making it suitable for colder environments.

- Neoprene vs. Spandex: Spandex offers stretch but lacks the water resistance and thermal insulation provided by neoprene, making neoprene the preferred choice for water sports and cold-weather gear.

Neoprene fabric’s unique blend of water resistance, flexibility, insulation, and durability makes it indispensable in high-performance, sports, and outdoor apparel.

How is Neoprene Fabric Made?

The production of neoprene fabric involves a series of steps designed to transform chloroprene monomers into a flexible, durable, and versatile synthetic rubber material. Here’s an overview of the process:

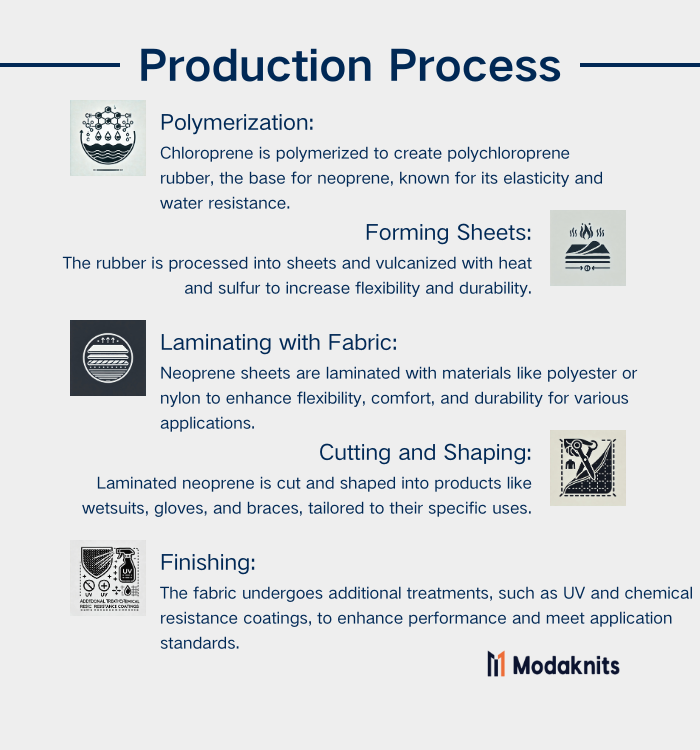

Production Process

- Polymerization: The process begins with the polymerization of chloroprene. This chemical reaction forms polychloroprene rubber, which serves as the foundation for neoprene fabric. The resulting material is characterized by its elasticity, water resistance, and thermal insulation properties.

- Forming Sheets: The polychloroprene is then processed into sheets. These sheets undergo vulcanization, a process that involves treating the rubber with heat and sulfur-based compounds to enhance its flexibility, strength, and durability. Vulcanization is essential to achieve the characteristic elasticity and toughness associated with neoprene.

- Laminating with Fabric: To increase the fabric’s functionality and comfort, the neoprene sheets are laminated with other materials like polyester, nylon, or spandex. This lamination process adds flexibility, durability, and stretchability, making the fabric suitable for diverse applications such as wetsuits, athletic wear, and medical braces.

- Cutting and Shaping: Once the laminated neoprene fabric is prepared, it is cut and shaped according to its intended use. This step is crucial for creating various products like wetsuits, gloves, braces, or other customized garments designed for different functions and industries.

- Finishing: The final stage involves additional treatments to enhance the neoprene fabric’s qualities, such as applying coatings to improve softness, flexibility, or resistance to UV rays and chemicals. These finishing processes ensure that the fabric meets the performance requirements for specific applications, especially in sports and outdoor gear.

Regions Known for Neoprene Fabric Production

- United States: The U.S. is one of the primary producers of neoprene fabric, specializing in high-quality versions used for professional wetsuits, athletic wear, and industrial applications.

- China: As a major textile manufacturing hub, China produces large quantities of neoprene fabric, often focusing on affordability and mass production for global markets.

- Japan: Known for its advanced technological capabilities, Japan manufactures high-performance neoprene, especially for sports and diving equipment, with a focus on innovation and quality.

The meticulous production process of neoprene fabric ensures its suitability for a wide range of applications, offering durability, flexibility, and water resistance essential for sportswear, outdoor gear, and more.

What Are the Types of Neoprene Fabric?

Neoprene fabric is available in several variations, each tailored to different applications based on its properties. These types ensure that neoprene can meet a variety of needs, from water sports to fashion and industrial uses.

- Standard Neoprene

This is the most common type of neoprene, known for its balance of flexibility, insulation, and water resistance. Standard neoprene is typically used in wetsuits, diving gear, gloves, and other protective clothing, providing essential thermal insulation and buoyancy for underwater activities. - Laminated Neoprene

Laminated neoprene consists of neoprene sheets bonded with additional fabrics such as nylon, polyester, or spandex. This combination enhances the fabric’s flexibility, durability, and comfort, making it ideal for sportswear, athletic apparel, and fashion items where both stretch and support are needed. - Perforated Neoprene

Perforated neoprene has small holes or perforations that improve breathability while still offering some degree of insulation. This type is especially suitable for fitness apparel and activewear, as it allows for better airflow during high-intensity activities, helping to regulate body temperature. - Textured Neoprene

This version features embossed or textured surfaces, adding visual and tactile interest. Textured neoprene is often used in accessories like bags, shoes, and fashion garments where surface grip or aesthetic appeal is important. The texture also helps enhance the durability of products by providing additional friction resistance. - Ultra-Thin Neoprene

Ultra-thin neoprene is designed for lightweight applications, offering flexibility and stretch without bulk. This type is suitable for garments where maximum mobility is essential, such as in yoga wear, performance sports clothing, or fashion items that require a sleek, streamlined look.

Each type of neoprene fabric provides unique characteristics, ensuring its versatility for a wide range of applications, from athletic and outdoor gear to fashion-forward pieces and industrial uses.

How is Neoprene Fabric Used in Textiles?

Neoprene fabric’s adaptability and unique properties make it a versatile material used across various fashion, sports, and industrial applications:

- Sportswear

Neoprene is widely used in wetsuits, swimwear, and diving gear due to its excellent insulation and water resistance. These characteristics help maintain body warmth and protect wearers in aquatic environments, making it essential for water sports and underwater activities. - Fitness and Athletic Wear

Its stretch and supportive properties make neoprene an ideal material for fitness apparel and compression garments, including workout tops, shorts, and braces. It provides the necessary flexibility and support for movement, enhancing performance during physical activities. - Fashion Apparel

Designers often utilize neoprene for contemporary fashion items such as dresses, jackets, and skirts. The fabric’s structure and ability to contour to the body provide a sleek, modern silhouette, making it popular in avant-garde and body-con fashion. - Accessories

Due to its durability and aesthetic appeal, neoprene is frequently used in accessories like bags, shoes, and belts. Its flexible nature allows for creative designs, while its resilience ensures that these products are long-lasting and weather-resistant. - Protective and Industrial Gear

In industrial settings, neoprene is employed for making gloves, knee pads, and medical braces. The fabric’s flexibility, cushioning, and support make it suitable for protective gear and medical applications, providing both comfort and protection.

Neoprene fabric’s broad range of applications highlights its versatility, making it a key material in industries from fashion to sportswear and safety equipment.

How Much Does Neoprene Fabric Cost?

The cost of neoprene fabric varies depending on factors such as type, quality, and production location. Here’s a detailed breakdown to help manufacturers make informed sourcing decisions:

Neoprene Fabric Costs in the United States

- Basic Neoprene Fabric: Prices typically range from $15 to $25 per yard. This basic version is often used in casual sportswear and accessories.

- Premium Neoprene Fabric: Higher-end types, including laminated, textured, or embossed neoprene, generally range from $30 to $50 per yard. These variants are designed for specialized applications like wetsuits or high-performance athletic wear, offering enhanced durability, insulation, or aesthetic appeal.

Neoprene Fabric Costs in China

- Basic Neoprene Fabric: In China, prices are more competitive, typically ranging from $8 to $20 per yard. Lower labor and production costs contribute to the reduced pricing, making China an attractive option for manufacturers looking for cost-effective sourcing.

- Premium Neoprene Fabric: For advanced versions like laminated or perforated neoprene, prices range from $25 to $40 per yard. These types still offer significant cost savings compared to those produced in the United States.

Factors Influencing Neoprene Fabric Prices

- Lamination and Texturing: Additional processes such as laminating neoprene with other fabrics (e.g., nylon or polyester) or adding textures or embossing increase the cost. These enhancements provide added flexibility, comfort, or style.

- Production Location: Manufacturing costs differ by region. Neoprene produced in China is typically less expensive due to lower labor and operational expenses. In contrast, U.S.-produced neoprene often costs more, reflecting stricter quality controls and higher production standards.

- Thickness and Density: Thicker and denser neoprene types, used for applications like diving suits and industrial protection, are more costly due to the increased material and processing required.

By leveraging competitive prices from regions like China, Modaknits can source high-quality neoprene fabrics that meet the needs of both high-performance and budget-conscious markets, ensuring that our products maintain both functionality and affordability.

How Does Neoprene Fabric Impact the Environment?

Neoprene fabric, while valuable for its durability and versatility, has both positive and negative environmental effects. Here’s a closer look at how its production and use affect the environment:

Positive Environmental Impacts

- Durability: One of neoprene’s strengths is its long lifespan. Garments and products made from neoprene tend to last longer, reducing the need for frequent replacements. This longevity can help lower textile waste over time, making it a more sustainable option compared to less durable materials.

- Versatility in Recycling: Some initiatives focus on recycling neoprene waste into new products, such as yoga mats, padding, or other durable items. These recycling efforts can reduce the environmental footprint by reusing materials that would otherwise end up in landfills.

Negative Environmental Impacts

- Non-Biodegradable: As a synthetic rubber material derived from petroleum, neoprene is not biodegradable. If neoprene products are not recycled or disposed of properly, they persist in the environment for long periods, contributing to landfill waste and environmental degradation.

- Chemical Processing: The production of neoprene involves the polymerization of chloroprene, which uses chemicals that can be hazardous if not managed correctly. Improper disposal of waste or emissions during the manufacturing process can lead to air, water, and soil pollution, impacting ecosystems and human health.

Sustainable Practices

- Recycling Programs: Some manufacturers are developing recycling programs to collect and repurpose used neoprene into new products, such as accessories or insulation materials. However, these programs are still limited in scale and accessibility, which challenges their effectiveness in reducing overall waste.

- Bio-Based Neoprene Alternatives: To address the environmental concerns of traditional neoprene, new bio-based alternatives are being developed. These eco-friendly versions aim to minimize reliance on petroleum-based materials, using natural resources like limestone or renewable plant-based sources instead. These alternatives have the potential to reduce the carbon footprint associated with neoprene production.

By understanding the environmental impact of neoprene fabric and supporting sustainable practices, manufacturers like Modaknits can contribute to reducing the ecological footprint of neoprene-based products while maintaining their performance and versatility.

Ensuring Neoprene Fabric Quality and Certification

At Modaknits, we are committed to upholding the highest standards for our neoprene fabrics, ensuring both quality and sustainability through strict adherence to globally recognized certifications and production practices.

Key Quality Indicators

- Strength and Flexibility: Neoprene is valued for its elasticity and durability. We ensure that our neoprene fabrics maintain these properties, making them suitable for a variety of applications, from activewear to protective gear. This focus guarantees that our products provide long-lasting performance and comfort.

- Water and Thermal Resistance: Our neoprene fabrics are designed to offer excellent water and thermal insulation, essential for applications such as wetsuits and outdoor wear. By sourcing premium neoprene, we ensure that our garments provide protection without compromising mobility or comfort.

Certifications and Sustainability

- OEKO-TEX® Certification: All Modaknits neoprene fabrics are certified under OEKO-TEX® Standard 100, confirming that they are free from harmful chemicals. This certification guarantees that our products are safe for consumers and have minimal environmental impact.

- ISO Standards: We comply with ISO standards for both quality management and environmental responsibility, ensuring consistent production quality while minimizing the ecological footprint of our neoprene manufacturing processes.

By prioritizing these certifications and quality measures, Modaknits ensures that our neoprene garments deliver high performance while aligning with the growing demand for sustainable and eco-friendly materials.

For more information about our fabrics or to explore our product catalog, please contact us.