fabric customization option

Fabric customization is pivotal in our garment production at Modaknits Apparel. We understand how crucial fabric choice is for the quality, comfort, and appearance of clothing, ensuring each piece reflects individual style and identity. We provide a wide range of fabrics to meet diverse needs.

Our extensive fabric options offer the flexibility to customize collections for various needs, ensuring garments are not only stylish but also functional. Choosing the right fabric enhances durability, comfort, and sustainability.

Guiding clients through fabric selection is key at Modaknits Apparel. With our textile expertise and industry experience, we meet the unique needs of each fashion line, bringing visions to life precisely as planned.Next, we will briefly introduce fabric selection, fabric processing, as well as fabric printing and embroidery.

Fabric Selection - Essential for Apparel Diversity

In apparel manufacturing, fabric choice is critical to garment quality. There are two key types: Fabric Knitting and Readily Available Fabric, each meeting specific industry needs.

Fabric Knitting allows for customized fabrics tailored to unique specifications, ideal for brands seeking distinctiveness in texture, weight, or composition. This method facilitates innovation, offering unique fabrics that highlight a brand’s uniqueness.

Readily Available Fabric involves choosing existing fabrics from suppliers, offering a quicker, cost-effective production method. Suitable for meeting deadlines or budget limits, it provides a variety of materials for flexible design options.

Both options have their benefits, influencing fabric selection based on vision, timeline, and budget. At Modaknits Apparel, we stress this choice’s significance, guiding clients to the optimal fabrics for their projects

Fabric Processing - Key to Textile Excellence

Fabric processing is crucial in textile manufacturing, enhancing fabric quality, look, and functionality. Fabric Washing and Fabric Dyeing are central, significantly affecting textiles for fashion.

This technology improves softness, removes contaminants, and controls shrinkage, preparing textiles for further production steps. It ranges from simple rinses to complex treatments like stone and enzyme washing, targeting specific finishes and ensuring fabric readiness without compromising quality.

This process introduces colors and patterns to textiles, using diverse techniques based on fabric needs and design goals. This step not only boosts fabric appeal but also enhances performance, like color retention and fade resistance, thanks to modern dyeing advances.

In essence, Fabric Washing and Fabric Dyeing are pillars of fabric processing, vital for producing industry-standard textiles. These steps ensure fabrics are visually attractive and high in quality and comfort, ready for garment making.

Fabric Printing and Embroidery - A Guide to Textile Decoration

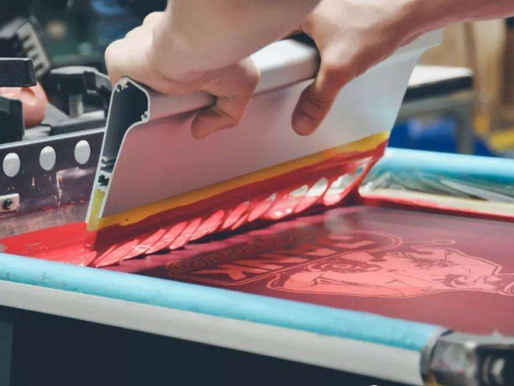

In apparel design, Fabric Printing and Embroidery are essential for adding aesthetic value to textiles. These techniques divide into Screen Printing, Digital Printing, and Embroidery, enhancing garments with unique visual and textural qualities.

this printing technique involves pushing ink through a screen onto fabric, favored for its durability and suitability for large orders. It’s known for vibrant, long-lasting designs that cater to various textile types.

This technology uses inkjet technology for detailed, colorful patterns directly on fabric. It excels in customization and small runs, offering designers freedom to create complex, high-resolution imagery efficiently.

This craft enriches textiles with needle and thread, providing a luxurious, handcrafted look. It’s versatile for adding personal or branded embellishments, known for its dimensional quality and durability.

These three methods, Screen Printing, Digital Printing, and Embroidery, serve as foundational techniques in fabric decoration, allowing for the creation of distinctive, high-quality apparel. Each plays a crucial role in the fashion industry, offering designers diverse options to bring their visions to life.

OUR PROCESS

Fabric Selection

Your dedicated representative will initially help you select the best fabric for your product.

Cut & Sewing

Once the fabric is selected, it is sent for Cut & Sew processes to make sure that the quality of the product is not compromised at all.

Customization

At this step, all the changes you need in terms of printing, add-ons and changes are done effectively.

Labeling

Once your product is finalized, we make sure that every piece has your label before it is sent to the packaging department

Packaging

The final product is ironed, folded with care and packed in the baggage of your choice to give it a premium look

Shipment

Once the order is packed and ready, it is sent for shipment to your location with minimum shipping time.

PREMIUM CLOTHING MANUFACTURING SERVICES

If you are genuinely looking for professionals in Apparel Designing and custom tshirt manufactures China & services,

Modaknits Apparel is the right choice for finest and long-lasting product quality.

CERTIFICATIONS

MODAKNITS Repsects Quality Standards