Joggers have evolved far beyond their athletic origins to become a cornerstone of modern fashion. Whether you’re dressing for comfort, performance, or street style, there’s a jogger style that fits the occasion—and your personal aesthetic. Following the success of Part 1, which covered silhouettes, cuts, and performance joggers, Part 2 takes a deeper dive into the world of materials and design innovations that define the jogger category today.

In this chapter, we’ll explore how different fabric types—from cotton and fleece to spandex blends and sustainable textiles—shape the functionality, comfort, and visual appeal of joggers. Whether you’re a brand developer, designer, or buyer, understanding these fabric-driven categories is essential for selecting or producing joggers that align with your customer’s needs, climate, and intended use.

Extra-Long Joggers

Extra-long joggers are the ultimate fusion of fashion-forward aesthetics and relaxed functionality. Defined by their elongated inseam and extended leg length, these joggers offer a bold, draped silhouette that breaks from traditional athletic fits. Popular among streetwear enthusiasts and tall consumers alike, extra-long joggers add dimension, movement, and edge to any outfit.

Technical Fabrication

Unlike standard joggers, extra-long joggers require fabric considerations that account for length, weight, and drape. Common materials include:

- Mid- to heavyweight French terry and cotton blends for structure

- Rayon or modal blends for enhanced fluidity and fall

- Brushed fleece for added volume and seasonal comfort

Fabric stretch (typically 5–10% spandex) is often incorporated to prevent restriction despite the added length. Designers must also manage weight distribution to avoid excessive sagging at the ankle.

Design & Construction Details

Extra-long joggers go beyond just “adding length.” They require thoughtful tailoring to maintain style, proportion, and function. Key construction features include:

- Inseam extensions of +4 to +8 inches over standard jogger lengths

- Stacked hems at the ankle for intentional bunching or layering effect

- Adjustable cuffs (elastic or zippered) to manage extra fabric volume

- Dropped crotch or tapered leg fit to avoid ballooning at the knee

- Flatlock seams to maintain comfort across extended garment areas

Some versions incorporate internal panels or double-layered knees to enhance durability, especially when the fabric drags on surfaces.

Target Audience & Use Cases

Extra-long joggers serve both niche style markets and practical needs:

| Segment | Motivation |

|---|---|

| Tall consumers | Need for proper length and ankle coverage |

| Streetwear community | Styling with stacked sneakers and layered looks |

| K-pop/Asian fashion fans | Inspired by elongated silhouettes |

| Loungewear buyers | Preference for oversized comfort and drape |

These joggers are often styled with high-top sneakers, chunky soles, or layered with longline tops to create a vertical aesthetic emphasis.

Manufacturing Considerations

From a production standpoint, extra-long joggers present several challenges and opportunities:

- Precise grading is crucial—especially in tall sizes—to avoid skewed proportions

- Increased fabric yield must be calculated into cost and weight logistics

- Hemming techniques must support stacked or adjustable drape without bulk

- Shrinkage control becomes vital, especially with cotton-based fabrics

- Reinforced seams are often added at stress points due to dragging potential

Brands targeting a global market must also consider regional height variations and offer “Tall Fit” size charts to aid conversion.

Brand Strategy & Differentiation

Extra-long joggers allow brands to tap into:

- Fashion-forward capsule collections for Gen Z and streetwear consumers

- Extended-size offerings without redesigning entire garment patterns

- Layered silhouettes trend prominent on social platforms like TikTok and Instagram

Differentiation can come from stacking techniques (raw-edge vs. elastic-finished), limited-edition fabrics (tie-dye, acid wash), or collaborations with influencers in the hip-hop, dance, and fashion scenes.

Split Hem Joggers

Split hem joggers offer a fresh twist on classic jogger silhouettes by incorporating side or front hem openings at the ankle. This subtle yet powerful detail enhances both visual appeal and functional mobility, making split hem joggers a standout choice in contemporary activewear and street fashion. Whether designed with zippers, raw edges, or stitched slits, the hem modification allows wearers to showcase footwear or enjoy a less restrictive leg opening.

Technical Fabrication

Fabric choices for split hem joggers must accommodate flexibility, durability, and clean edge finishes. Common textile options include:

- Cotton-spandex blends for comfort and moderate stretch

- Polyester performance knits with wrinkle resistance and mobility

- Tech fleece or interlock fabrics for structural form and hem integrity

Since the slit area can become a point of wear and tear, reinforced stitching or bar tacking is often added at the start or end of the slit. If the split hem is zippered, the surrounding fabric must support hardware without puckering or distortion.

Design & Construction Details

Split hem joggers are defined by their distinct cut at the cuff. These cuts can be engineered for both style and function:

- Side splits (typically 3–6 inches long) for movement and ankle display

- Front splits (centered along shin) for vertical elongation effect

- Zippered splits for adjustable opening width and techwear aesthetics

- Raw-edge hems for casual, streetwear vibes

- Elastic-free cuffs to allow clean stacking over sneakers or boots

Design must ensure that hem alignment stays symmetrical and that the opening doesn’t interfere with taper or leg drape. Many styles also include facing or binding along the slit edges for clean, durable finishes.

Target Audience & Use Cases

Split hem joggers attract both performance-driven and fashion-conscious buyers:

| Segment | Preference |

|---|---|

| Sneaker enthusiasts | Visibility for footwear with stacked designs |

| Streetwear fans | Edge, movement, and visual break from tradition |

| Casual-wear consumers | Comfortable mobility with enhanced style |

| Fitness/lifestyle | Ease of ankle movement and temperature control |

They are particularly popular in urban fashion, dancewear, and fashion-forward gym settings, where footwear and movement are part of the style narrative.

Manufacturing Considerations

Split hem joggers require heightened attention in production:

- Pattern accuracy ensures both sides of the split align and fall evenly

- Reinforcement at split start/stop points prevents tearing during wear

- Zipper installation must not warp fabric—requiring stay tape or interfacing

- Hem edge finishes should balance visual appeal with durability—raw, bonded, or double-folded

Extra steps like mock-ups or fabric tension tests may be necessary to avoid gaping or fraying at the split, especially in styles without zipper closure.

Brand Strategy & Differentiation

Split hem joggers are ideal for:

- Limited-edition streetwear collections

- Technical-athleisure crossovers

- Unisex offerings with a fashion-forward edge

To differentiate, brands can play with asymmetrical splits, contrast taping or zipper colors, or offer convertible split lengths. Influencer collaborations that highlight sneaker styling with joggers can also create strong visual campaigns.

Elastic Waist Joggers

Elastic waist joggers represent one of the most timeless and widely adopted styles in the jogger category. Built for ease, versatility, and universal fit, they are the everyday go-to for both casual wearers and performance-driven consumers. While the design may appear simple, the construction and material selection behind a reliable elastic waistband can significantly impact the garment’s fit, comfort, and longevity.

Technical Fabrication

The fabric used in elastic waist joggers must balance softness, durability, and stretch compatibility. Common base fabrics include:

- Cotton blends (60–80% cotton with polyester or spandex for softness + breathability)

- Polyester-spandex knits for performance and resilience

- Loopback fleece or French terry for warmth and moisture control

However, the real technical aspect lies in the elastic waistband system. Most elastic waist joggers use:

- Encased elastic bands (1.5–2 inches width) within a fabric tunnel

- Exposed elastic waistbands for a sportier aesthetic

- Elastic + drawstring combo, allowing adjustable tension and added security

Premium joggers often use woven non-roll elastic, which maintains shape after extended wear and laundering.

Design & Construction Details

Though seemingly straightforward, the waistband design demands precision:

- Stitching channels must hold the elastic in place to prevent twisting

- Bar tacking or reinforced side seams are applied for stress durability

- Flat drawstrings, barrel tips, or hidden inner cords provide style and utility

- Mid-rise or high-rise cuts influence torso fit and comfort

In terms of leg structure, elastic waist joggers may feature:

- Tapered legs with cuffed ankles

- Straight or relaxed fit legs for more room

- Minimal side seam bulk to maintain comfort when sitting or stretching

Target Audience & Use Cases

Elastic waist joggers are truly universal in appeal. They cater to:

| Segment | Preference |

|---|---|

| Casual consumers | Easy pull-on wear and relaxed fit |

| Sports & gym users | Secure waistband with movement flexibility |

| Elderly markets | Non-restrictive waist for daily comfort |

| Maternity/postpartum | Soft stretch without pressure on the belly |

This style is also popular in uniform production, hospitality loungewear, and work-from-home fashion due to its versatility and ease of wear.

Manufacturing Considerations

Elastic waist joggers offer production simplicity, but with potential pitfalls:

- Elastic channel precision is crucial—too tight and the waistband curls; too loose and the elastic shifts

- Elastic insertion must be tension tested to avoid excessive stretch or breakage over time

- Fabric and waistband width must be proportioned for visual balance

- Drawstring grommets (if external) need reinforcement for long-term durability

- Waistband height grading needs special attention in plus-size and kidswear segments

Proper tension calibration during production ensures consistent sizing, especially in large batches.

Brand Strategy & Differentiation

Elastic waist joggers are often used as:

- Entry-level products in a jogger collection

- Private label essentials for retailers seeking basic SKUs

- Add-on items in lifestyle and activewear bundles

To stand out, brands can innovate through:

- Organic cotton or bamboo fabrics for sustainability

- Smart elastic systems like jacquard-branded bands or tech stretch inserts

- Custom label integration within waistbands

- Inclusive size range offerings from XXS to 5XL

Even minor upgrades like branded aglets, reinforced waistband lining, or logo-printed inner tapes can elevate perception in the consumer’s eyes.

Tech Joggers

Tech joggers are where function meets futuristic fashion. Designed with advanced fabrics and smart construction, tech joggers go beyond aesthetics—they integrate performance features, weather resistance, stretch mobility, and utilitarian design to meet the demands of modern urban life and active lifestyles. These are joggers reimagined for athletes, commuters, travelers, and digital nomads alike.

Technical Fabrication

The defining feature of tech joggers is the use of high-performance technical fabrics, engineered for adaptability and durability. Common materials include:

- Nylon-spandex blends with water-resistant coatings (DWR)

- Recycled polyester with UV protection and moisture-wicking finishes

- Softshell or ripstop fabrics for durability and wind resistance

- Laser-cut ventilation zones using bonded mesh for breathability

These fabrics are lightweight, quick-drying, abrasion-resistant, and often include anti-odor or anti-static treatments. Some tech joggers also incorporate thermal regulation technologies like Outlast® or temperature-adaptive yarns, making them wearable across climates.

Design & Construction Details

Tech joggers are precision garments, often using laser cutting, bonded seams, and ergonomic patterning. Key construction features include:

- Gusseted crotch and articulated knees for unrestricted movement

- Zippered utility pockets, often hidden or bonded

- Tapered leg with elastic or adjustable hem zips

- Minimalist, seamless or taped construction to reduce bulk

- YKK water-resistant zippers, magnetic snap closures, or even NFC-tagged smart pockets

Waistbands may be elastic, drawstring, or even semi-rigid with low-profile buckle systems or adjustable toggles, designed for minimal bounce during high activity.

Target Audience & Use Cases

Tech joggers target a more performance-driven and function-oriented consumer segment. Common use cases include:

| Segment | Preference |

|---|---|

| Urban commuters | Lightweight, breathable joggers with secure storage |

| Active travelers | Packable, wrinkle-resistant, and quick-drying joggers |

| Fitness & training | 4-way stretch for pre/post-workout wear |

| Outdoor/athleisure | Durable, weather-resistant styles for hiking or biking |

| Techwear enthusiasts | Futuristic silhouettes and engineered functionality |

They also align with cross-functional wardrobes, serving as hybrid apparel for work, travel, and exercise.

Manufacturing Considerations

Producing tech joggers requires high-precision machinery and specialized expertise. Key considerations include:

- Taped or bonded seams demand controlled lamination equipment

- Patterning must support stretch and articulation zones to prevent restriction

- Multiple fabric layer integration (e.g., mesh lining + shell) requires precision stitching

- Waterproof zippers and reflective elements must pass function/durability tests

- Small batch prototyping is often necessary due to complexity

Factories must have experience with techwear or outdoor garment construction, as standard jogger lines may lack the capability to handle such complexity.

Brand Strategy & Differentiation

For brands, tech joggers are ideal for:

- Positioning in the performance-meets-lifestyle segment

- Targeting Gen Z and Millennial techwear enthusiasts

- Commanding premium price points ($80–$150+)

Differentiators can include:

- Branded technical fabrics (e.g., Schoeller®, Toray®, Polartec®)

- Modular features like removable cargo panels, convertible lengths

- Storytelling through usage scenarios (urban hiking, tactical commuting, smart packing)

- Sustainability messaging using recycled performance fibers and bluesign® certified mills

Many brands pair tech joggers with modular outerwear, hybrid tees, or compression tops to build complete capsule collections.

Double-Layer Joggers

Double-layer joggers are not just a stylistic evolution—they represent an intentional merge of performance, modesty, and enhanced functionality. Originally designed for activewear purposes, this jogger style has grown into streetwear and athleisure spaces due to its unique structure and hybrid appeal.

Construction Logic & Technical Structure

Double-layer joggers are defined by their integrated dual-fabrication system—usually consisting of:

- Inner base layer: Often a compression short, mesh short, or soft-touch jersey fabric

- Outer jogger shell: Typically made from lightweight polyester, nylon blends, or French terry cotton

The construction includes a fixed or floating inner lining that serves either as support (compression) or modesty (coverage) while the outer layer provides the jogger look. Depending on the design, they can be constructed as:

- Stitched-in double layer (common in performance-focused joggers)

- Detachable or modular dual layer (seen in high-concept fashion joggers)

- Panel overlap construction, where visual depth is added via front/back layering

Fabrication Insights

Fabric combinations vary based on the product’s end use:

Inner Layer Options:

- Moisture-wicking polyester mesh for breathability

- Compression spandex-nylon blends for muscle support

- Modal/cotton for comfort in loungewear-focused versions

Outer Layer Options:

- Woven polyester with mechanical stretch for structure

- Lightweight French terry for comfort and drape

- Technical shell fabrics for durability and weather resistance

The use of different GSM ratings between layers is critical—inner layers are typically thinner and skin-friendly, while outer layers hold form and aesthetics.

Performance & Functional Benefits

Double-layer joggers offer more than just a layered look. They serve distinct purposes across use cases:

| Use Case | Functional Benefit |

|---|---|

| Sports & running | Compression + modesty; eliminates need for separate liners |

| Gym & training | Wicking base + abrasion-resistant outer shell |

| Streetwear | Layered aesthetics with ventilation or slit details |

| Cold weather layering | Added insulation without the bulk of traditional fleece |

Features such as laser-cut vents, hidden pockets in the base layer, or adjustable drawcords between layers are now common in premium designs.

Target Demographic & Style Preferences

Double-layer joggers appeal to both performance-driven consumers and style-conscious urban wearers. Key demographics include:

- Young male gym-goers who prefer layered looks with compression built-in

- Women seeking coverage during squats or high-motion workouts

- Gen Z consumers influenced by techwear and layered silhouettes

- Modest activewear segments in Middle Eastern and Southeast Asian markets

Designs with side slits, asymmetric hemlines, or layered color blocking also contribute to the popularity in fashion-forward markets.

Manufacturing Considerations

Producing double-layer joggers demands greater attention to inner-outer layer alignment and stitching precision. Key challenges include:

- Stretch compatibility between two fabrics—avoiding restriction during movement

- Flatlock or coverstitching at high-friction seams to avoid bulk and irritation

- Panel integration that prevents riding-up of the inner layer

- Batch consistency during layering, especially when using curved hem overlap

Production lines must be experienced in athleticwear or technical garment assembly to execute both aesthetic and performance features seamlessly.

Brand Strategy & Differentiation

Double-layer joggers offer strong value as hybrid garments. They allow brands to:

- Position in both activewear and casualwear segments

- Justify premium pricing via added construction and material use

- Stand out visually through architectural silhouettes

Brands often name these joggers with performance-centric or futuristic names like:

“LayerFlex™”, “Built-In Training Joggers”, or “DualForm Joggers” to appeal to both techwear and gym consumers.

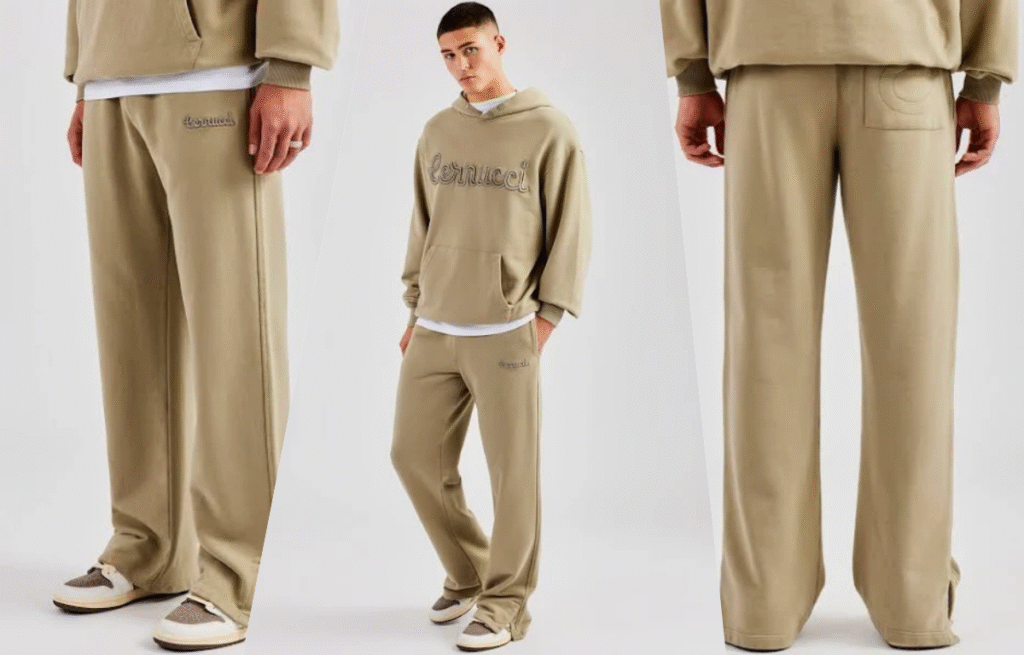

American Sport Joggers

American Sport Joggers pay homage to the golden age of U.S. athleticwear—drawing inspiration from varsity teams, collegiate sweats, and iconic 80s-90s gym silhouettes. These joggers are more than nostalgic apparel; they blend retro charm with modern functionality, making them a staple in both performance and streetwear categories.

Historical Design Influence

The roots of American Sport Joggers can be traced to mid-20th century U.S. athletics, when heavyweight sweatpants became standard-issue gear for high school and college teams. Key inspirations include:

- Varsity/collegiate sportswear aesthetics with block-letter prints or applique

- Boxy, relaxed silhouettes that prioritize movement and comfort

- Elastic hems and ribbed cuffs, originally meant to retain warmth during warmups

Today’s versions maintain this heritage while integrating performance materials and tailoring to modern preferences.

Fabrication Details

Classic American joggers were made with 100% heavyweight cotton fleece (350–450 GSM). Contemporary designs now incorporate:

- Cotton-polyester blends for better moisture control and shape retention

- Brushed-back fleece interiors for superior softness and warmth

- Rib-knit gussets or side panels to enhance flexibility

- Garment-dyed finishes for a washed vintage effect

Premium versions may feature loopback terry for a breathable midweight option, especially popular in transitional seasons.

Design Features & Silhouette

Modern American Sport Joggers typically feature:

| Element | Description |

|---|---|

| Waistband | Wide ribbed elastic band with external drawstring |

| Pockets | Slash hand pockets and single back patch pocket |

| Logo/Branding | Embroidered script, applique logos, or varsity letters |

| Fit | Slightly relaxed with a tapered leg or classic straight |

| Cuff Finish | Ribbed cuffs or open hem depending on the design variant |

Some high-end adaptations integrate zippered ankle openings, mesh pocket linings, or thermal waffle liners to appeal to activewear markets.

Target Market & Use Scenarios

American Sport Joggers appeal to a wide audience that values heritage, comfort, and authenticity. Typical user profiles include:

- College students and alumni who resonate with varsity-inspired looks

- Lifestyle consumers seeking a “Made in USA” nostalgic athletic vibe

- Streetwear fans pairing vintage joggers with graphic hoodies or oversized tees

- Athletes and teams using them as warmup apparel in cooler weather

Brands often market these joggers with emotional storytelling: “built like your dad’s college sweats” or “heritage athleticwear, redefined.”

Manufacturing Considerations

Key aspects of producing American Sport Joggers include:

- Heavyweight fabric handling: requires industrial machines with strong feed

- Stitch type selection: flatlock or reinforced overlock stitching for durability

- Ribbing quality: cuffs and waistbands must use dense, recovery-tested rib knits

- Print/embroidery precision: collegiate logos or heritage graphics require exact placement and quality control

Brands focused on authenticity may demand USA-based production or heritage knit mills, which impacts sourcing and cost structure.

Brand Positioning Strategy

American Sport Joggers are often positioned under “Heritage Lines”, “Collegiate Collections”, or “Athletic Revival” capsules. Differentiators can include:

- Origin authenticity: e.g., “Made in USA” label, old-school factories

- Sustainable updates: organic cotton fleece or recycled polyester blends

- Limited edition collaborations with colleges, sports teams, or retro brands

Examples of successful market players include Champion Reverse Weave, Russell Athletic Vintage, and premium lifestyle labels like Reigning Champ or Todd Snyder x Champion.

British Minimal Joggers

British Minimal Joggers exemplify the refined aesthetic often associated with U.K. design philosophy—clean lines, neutral palettes, and a focus on timeless tailoring. Unlike flashy or logo-heavy joggers, these pants speak through subtlety and precision, catering to those who appreciate fashion that whispers rather than shouts.

Design Philosophy: Minimalism with Structure

British minimalism isn’t just about “less is more”; it’s about precision, proportion, and versatility. These joggers often draw inspiration from British tailoring traditions but reinterpret them in a relaxed, modern silhouette. Hallmark features include:

- Flat front design without bulky drawstrings or branding

- Streamlined side seams and internal pockets to reduce visual clutter

- Matte-finish trims, often tonal or hidden for a clean aesthetic

- Tapered legs with precise ankle finishes, typically cuffless or lightly hemmed

The aim is to create wardrobe staples that seamlessly transition between casual, smart-casual, and even business-casual settings—ideal for urban professionals or minimalist wardrobes.

Fabrication: Elevated Essentials

Material choice is pivotal. British minimal joggers often opt for luxury basic fabrics that are refined but never loud. Common fabrications include:

- Cotton-modal blends for a soft, fluid drape with a matte finish

- Double-knit viscose or ponte for structure and wrinkle resistance

- Brushed interlock knits offering comfort and surface cleanliness

- Technical twill weaves that resemble suiting but stretch like activewear

In high-end variants, you’ll find sustainable materials like organic cotton or TENCEL™ blends, in keeping with the eco-conscious ethos of modern British fashion.

Tailoring Details & Silhouette Precision

These joggers borrow from traditional suiting principles:

| Feature | Function |

|---|---|

| Hidden waistband systems | May use side tab adjusters or inner elastic |

| Minimal topstitching | Preserves clean lines, often done with blind stitch seams |

| Subtle pleats or darts | Enhances shaping without visual noise |

| Welt or no-back pockets | Offers storage while keeping a sleek rear view |

| Inseam gussets or darts | Enhances mobility without compromising the silhouette |

This attention to construction discipline sets them apart from mass-produced basics and appeals to customers looking for premium craftsmanship.

Target Market & Use Cases

British Minimal Joggers resonate with a specific demographic:

- Urban professionals who value functional elegance

- Minimalist consumers curating capsule wardrobes

- Creative industries personnel (designers, architects) preferring elevated casual wear

- Travelers looking for refined yet comfortable airport-to-meeting outfits

They’re often paired with knit polos, crew neck sweaters, or wool jackets—emphasizing a refined layering strategy rather than athleisure styling.

Manufacturing Notes

Producing British minimal joggers requires:

- Precision flat-seam sewing to avoid puckering or distortion on minimal seams

- Tightly controlled fabric cutting to maintain symmetrical, clean lines

- Structured waistband fusing for shape retention without visible bulk

- Higher QA standards due to the visibility of any minor flaw on solid fabrics

Bulk manufacturing must be tightly managed, as these joggers are often marketed as “elevated essentials” with little room for error.

Branding & Positioning Strategy

British Minimal Joggers align best with quiet luxury or contemporary minimalist brand stories. Key differentiation strategies include:

- No visible logos or only tone-on-tone embroidery

- Curated capsule drops rather than trend-chasing SKUs

- Emphasis on tailoring and fit in marketing campaigns

- Sustainability storytelling as part of brand ethos

Brands like Sunspel, Oliver Spencer, and Arket embody this approach—targeting discerning buyers who appreciate detail and restraint.

French Chic Joggers

British Minimal Joggers represent a refined, understated approach to casualwear. Rooted in the U.K.’s long-standing tradition of precision tailoring, these joggers combine structured silhouettes with relaxed functionality—making them a go-to choice for style-conscious professionals, creatives, and modern minimalists. They’re not just about comfort; they’re about quiet elegance and wearable architecture.

Design Philosophy: Simplicity, Precision, and Proportion

British minimalism in apparel is defined by a commitment to clean design, muted detail, and architectural structure. British Minimal Joggers follow this ethos with:

- Streamlined silhouettes: Often slim or tapered with no unnecessary bulk.

- Clean finishes: Hidden seams, minimal visible stitching, and no external logos.

- Tailored inspiration: Influences from traditional British trouser cuts, reimagined in knitwear or technical fabrics.

Every element is intentional, from pocket placement to the absence of embellishment. These joggers are designed to fade into the outfit, yet subtly elevate the overall look.

Fabrication: From Natural Elegance to Technical Refinement

Fabric plays a defining role. The ideal British Minimal Jogger uses high-grade, often sustainable materials that prioritize feel and structure:

| Fabric Type | Benefits |

|---|---|

| Organic cotton-modal blend | Soft, breathable, and drapes beautifully without cling |

| Ponte double-knit | Adds structure without stiffness, ideal for a tailored look |

| Viscose-polyester blends | Wrinkle-resistant, smooth surface finish |

| Premium tech jersey | Lightweight, travel-friendly, and fluid |

Advanced finishing techniques—such as enzyme washing or silicon softening—are common to ensure a sleek surface and tactile richness.

Construction Details: Where Tailoring Meets Casualwear

Manufacturing British Minimal Joggers requires attention to fit precision and finish cleanliness. Common features include:

- Concealed waistband systems: Elastic hidden inside fused waistbands or side-tab adjusters.

- Flatlock seams or blind stitching: Minimizes visual interruption and prevents seam bulk.

- Minimalist pocket construction: Welt or inseam pockets for a sleek silhouette.

- Cuffless hems or lightly tapered finishes: To avoid the “sweatpant” feel while maintaining comfort.

Some models also feature pressed front seams or darting to mimic suiting trousers—ideal for smart casual or elevated everyday wear.

Functionality & Use Cases

British Minimal Joggers aren’t just stylish—they’re functional in a lifestyle sense. Popular among:

- Urban creatives: Designers, architects, and tech professionals who want comfort without compromising sharp aesthetics.

- Minimalist wardrobe users: Consumers who value quality, versatility, and timelessness.

- Business casual circles: When paired with polos or knitwear, these joggers can replace chinos.

They’re also great for travel, thanks to wrinkle-resistant fabrics and stretch-based comfort—essential for long commutes or flights.

Production Notes & Manufacturing Standards

To maintain the visual and structural integrity of this jogger type, manufacturing must follow higher standards:

- Pattern cutting must be symmetrical and clean, especially with drapey fabrics that show imperfections.

- Edge finishing must be invisible—blind hemming, turned-under waistbands, or bonded seams.

- Fabric inspection is critical, since smooth surfaces show flaws more easily.

- Sizing must be consistent across batches, as small deviations affect the streamlined fit.

This category is better suited to factories with tailoring experience, not just athletic or casualwear production.

Branding Strategy & Market Positioning

British Minimal Joggers fit within contemporary, slow-fashion, or premium lifestyle brand categories. Ideal branding approaches include:

- Understated visual identity: Tone-on-tone logos, if any.

- Emphasis on construction and quality in marketing copy.

- Storytelling around fabric sourcing and ethical production.

- Capsule collection drops rather than fast-fashion cycles.

Successful examples of this strategy include Sunspel, Margaret Howell, and Oliver Spencer—brands that champion minimalism with substance.

Japanese Minimalist Joggers

Japanese Minimalist Joggers are the embodiment of function-driven design—where every seam, fold, and fabric choice serves a purpose. Inspired by Japan’s long-standing philosophy of minimalism, these joggers strip away excess, focusing instead on clean lines, functional silhouettes, and subtle craftsmanship. They’re not just garments—they’re design statements rooted in thoughtfulness.

At the core of Japanese minimalist fashion is the belief that less is more. This approach is reflected in every design decision:

- Monotone aesthetics with zero embellishment

- Straight or slightly tapered leg lines for a clean silhouette

- Invisible or seamlessly integrated pockets

- Minimal seam exposure—often with internal finishing or binding

- Drop crotch or panel manipulation to allow movement without disrupting lines

These joggers challenge conventional Western sporty designs by focusing on ease, silhouette, and movement harmony, often blurring the line between loungewear and contemporary fashion.

Fabrication: Texture Over Loudness

Rather than flashy prints or graphics, Japanese Minimalist Joggers emphasize the tactile quality of fabric. Ideal fabric selections include:

| Fabric Type | Characteristics |

|---|---|

| Cotton-linen blends | Naturally breathable with a soft, raw hand-feel |

| Textured woven cotton | Often dyed using traditional Japanese methods (e.g., garment-dyed or sulfur dye) |

| Smooth tencel twill | Fluid drape for straight-leg silhouettes |

| Washed canvas or selvedge | For structured minimalism with utilitarian edge |

The emphasis is on raw finishes, light garment washes, and natural aging, which are aligned with the wabi-sabi aesthetic—embracing imperfection and organic evolution over time.

Construction Techniques: Clean and Purposeful

Manufacturing Japanese minimalist joggers requires meticulous attention to structure and proportion. Key construction notes include:

- French seams or bound interiors to keep outside lines smooth

- Elastic waistbands integrated with self-fabric to avoid bulk

- Hidden zippers or snap closures instead of visible hardware

- Gusseted crotch or drop-seat cuts to improve range of motion while keeping exterior minimal

- Neutral topstitching or no topstitching to avoid visual noise

Unlike mass-market joggers, these require tailored assembly and quality control, especially for garments with subtle textural contrasts or undyed fabric tones.

Target Audience & Market Niche

This style appeals to a very specific and growing audience:

| Customer Segment | Characteristics |

|---|---|

| Urban creatives | Looking for quiet, intentional design with uniqueness |

| Slow fashion consumers | Seek timeless pieces made with sustainability and craftsmanship |

| Techwear and Japanese fashion fans | Inspired by designers like Yohji Yamamoto, Issey Miyake, and Uniqlo U |

| Minimalist lifestyle followers | Prioritize modularity, utility, and comfort over trend-driven fashion |

These joggers thrive in curated lifestyle stores, boutique online platforms, and designer-led collections.

Manufacturing Requirements & Strategic Positioning

For clothing manufacturers, producing Japanese minimalist joggers involves:

- Pattern mastery—asymmetry, drop crotch, and layering require high accuracy

- Fabric sourcing partnerships—especially for organic Japanese denim, indigo dyes, and raw cotton

- Smaller batch production to preserve artisanal quality

- High-end finishing like flatlock seams, hand-pressing, and slow-speed sewing

Strategically, brands positioning this jogger line should emphasize:

- Limited edition drops or made-to-order models

- Storytelling via design origin and material sourcing

- Tie-ins with Japanese culture—Zen, utility, or traditional craftsmanship

Korean Slim Joggers

Korean Slim Joggers perfectly capture the fusion of tailored aesthetics and street-inspired flair that defines contemporary Korean fashion. These joggers are more than just tapered sweatpants—they reflect a cultural blend of structure, minimalism, and pop influence, offering a refined silhouette that works equally well in casual and elevated settings.

Style Philosophy & Design Direction

Korean fashion—especially men’s and unisex streetwear—often emphasizes lean, clean lines with subtle standout features. Korean Slim Joggers reflect this design approach:

- Tapered but not skin-tight fit through the leg

- Cropped or ankle-skimming hems to show off footwear (key in K-style)

- Minimal topstitching with smart placement of seams

- Integrated pintuck or vertical paneling to elongate the legs

- Built-in stretch for mobility, while retaining form

The key aesthetic is understated precision—making them suitable for layered streetwear, airport fashion, or casual workwear looks.

Fabric Selection & Texture Preferences

Korean Slim Joggers typically use refined, mid-weight stretch fabrics with a smooth surface and structured drape. Popular options include:

| Fabric Type | Description |

|---|---|

| Stretch twill or ponte | Offers polished structure with comfortable movement |

| Tech-infused polyester blends | Often wrinkle-resistant and moisture-wicking, ideal for urban living |

| Lightweight scuba or neoprene | Smooth, clean finish that holds its shape and elevates the look |

| Viscose-spandex blends | Adds fluidity without compromising fit |

These joggers often avoid the slouchiness of fleece or loose-knit jerseys, opting instead for tailored, semi-formal textile choices—reinforcing their wearable versatility.

Construction & Fit Specifics

The technical construction of Korean Slim Joggers is focused on precision fit and visual elongation. Notable design features include:

- Flat or hidden elastic waistband for a clean, modern waistline

- Front pintucks or center seams that replicate tailored trousers

- Zippered side pockets or welt pockets with minimalist flaps

- No cuff or a micro cuff—differentiating them from Western joggers

- Laser-cut hems or bonded edges in high-end styles for ultra-clean finish

Fit grading must be precise, as the slim cut requires balance between mobility and contour—particularly important for multi-gender or unisex styles.

Market Segment & Style Positioning

Korean Slim Joggers primarily target a younger, fashion-forward demographic, including:

| Target Group | Key Preferences |

|---|---|

| K-pop influenced consumers | Emulate idol airport fashion and casual dance rehearsal wear |

| Urban streetwear buyers | Slim silhouette that pairs with oversized tops or sneakers |

| Casual smartwear seekers | Clean jogger alternative to chinos or jeans |

| Fashion-forward unisex markets | Androgynous style that blends tailoring with street culture |

They’re often sold as part of two-piece sets or capsule wardrobes, often found in Korean boutique brands or on global fashion platforms like YesStyle and W Concept.

Manufacturing Requirements

Producing Korean Slim Joggers requires attention to:

- Fabric cutting accuracy to ensure consistent slim taper

- Minimal seam bulk—especially with bonded or laser-edge finishes

- Durable stretch threads and elastic tension control for long-term shape

- Specialized waistband designs, often flat or fused for clean looks

- Packaging and folding must preserve silhouette (rolled or flat-packed only)

To meet Korean market standards, fit testing on multiple body types and low MOQ color options (e.g., black, charcoal, khaki, ivory) are often expected.

Hip-Hop Joggers

Hip-Hop Joggers are more than just a garment—they’re a cultural symbol born from the evolution of streetwear, music, and identity. Defined by their bold silhouettes, functional elements, and attitude-driven details, these joggers blend fashion with self-expression, resonating with a diverse, global audience.

Origins and Cultural Relevance

The roots of Hip-Hop Joggers trace back to 1980s and 1990s street fashion in New York City, where music, dance, and rebellion shaped wardrobe choices. Baggy silhouettes, functional cargo details, and attention-grabbing logos were staples of the era. Joggers became the go-to bottom for:

- Breakdancers needing mobility

- Rappers expressing individuality

- Youth signaling affiliation with hip-hop culture

Today’s Hip-Hop Joggers pay homage to that heritage with oversized fits, utility elements, and genre-defining aesthetics.

Fabric & Material Analysis

To meet both style and performance demands, Hip-Hop Joggers often use medium to heavy-weight fabrics that balance structure and ease. Popular options include:

| Fabric Type | Purpose |

|---|---|

| 100% Cotton French Terry | Breathability and softness for casual wear |

| Brushed Fleece | Cozy, structured feel—ideal for oversized shapes |

| Twill or Cotton-Spandex Blends | Adds stretch to structured styles without losing durability |

| Nylon or Crinkle Polyester | Gives a retro tracksuit vibe—moisture-wicking and bold |

Durability and drape are prioritized, especially for baggy and wide-leg styles. Weight (GSM) plays a key role—250–380 GSM is common for performance-driven joggers, while lightweight woven fabrics may be used for shell pants and parachute joggers.

Design Elements & Construction Features

What sets Hip-Hop Joggers apart is their bold construction language. Key features often include:

- Drop-crotch or low-rise construction for exaggerated proportions

- Elastic or drawstring waistbands with visible branding or logos

- Oversized cargo pockets with Velcro or zip closures

- Ribbed or elastic cuffs for a tapered leg finish

- Graphic prints, embroidery, or appliqués—e.g., graffiti, patches, slogans

- Contrast paneling or reflective trims inspired by performance gear

New-gen Hip-Hop Joggers may also include techwear crossovers, with straps, loops, or buckles—fusing fashion with tactical design.

Audience Segmentation & Styling Context

Hip-Hop Joggers cater to a wide range of consumers influenced by music, dance, and youth culture:

| Audience | Style Motivation |

|---|---|

| Streetwear enthusiasts | Statement-making joggers as style centerpieces |

| Dancers & performers | Prioritize movement, durability, and breathability |

| Sneakerheads | Seek tapered cuffs to showcase high-end sneakers |

| Gen Z creators & influencers | Fashion-forward content and self-branding |

They’re often styled with graphic tees, oversized hoodies, varsity jackets, or crop tops, depending on gender and subculture.

Manufacturing & Production Considerations

Creating authentic Hip-Hop Joggers involves more than standard jogger production:

- Loose-fit patterns must be drafted to avoid excess bulk

- Pocket construction adds complexity—requires bar-tacking for reinforcement

- Printing/embroidery must maintain fabric integrity under stretch and wash

- Custom trims (zippers, buckles, straps) require sourcing and secure attachment

- Waistbands and cuffs need robust elasticity for frequent movement and wear

It’s also common for brands to introduce limited-edition runs, with exclusive artwork or artist collaborations—making low-MOQ flexibility and rapid sample turnaround essential for B2B success.

Skate Joggers

Skate joggers are a subcategory of athleisure wear that merge the durability and function of skate apparel with the comfort and style of modern joggers. Originally rooted in skateboarding culture, this jogger style has evolved into a wardrobe staple for both skaters and streetwear enthusiasts seeking unrestricted movement, impact resistance, and subcultural identity.

Purpose-Driven Design Origin

Skateboarding is a high-impact sport that demands garments capable of withstanding constant friction, repetitive falls, and dynamic body movement. Unlike conventional joggers, skate joggers are engineered with:

- Reinforced construction zones (especially knees and seat)

- Relaxed fits for mobility

- Durable, abrasion-resistant fabrics

- Secure waistband and ankle features for safety during tricks

The skate jogger isn’t just a style—it’s a functional necessity in a physically demanding subculture.

Fabric Selection & Durability Standards

Fabric is the cornerstone of skate jogger functionality. Common textile choices include:

| Fabric Type | Key Advantages |

|---|---|

| Cotton-Twill (200–280 GSM) | Durable, breathable, softens with wear |

| Cotton-Poly Blends (260–320 GSM) | Added strength and shrink resistance |

| Canvas or Ripstop Cotton | High tear-resistance for serious skating |

| Stretch Woven Twill (2–5% Spandex) | Enhances flexibility without compromising strength |

Finishing techniques such as enzyme washing or silicone softening are used to improve hand-feel without weakening the fabric’s abrasion resistance.

Construction Details & Functional Features

Effective skate joggers are built with enhanced technical construction, reflecting the needs of active skaters:

- Double or triple-stitched seams to withstand impact and repeated wash

- Articulated or reinforced knees to support crouching, flipping, and landing

- Gusseted crotches for maximum leg spread during tricks

- Elastic or drawstring waistbands for secure fit during motion

- Adjustable hems (e.g. toggle cords or cuffed ankles) to prevent fabric interference with wheels

- Low-profile side or cargo pockets to reduce bulk while offering storage

Some designs include hidden zip pockets, interior mesh panels, or breathable laser-perforated zones for improved airflow during high-intensity skating sessions.

End User Profile & Style Context

Skate joggers primarily appeal to:

| Audience | Preferences |

|---|---|

| Skaters (amateur/pro) | Function-first: durability, fit, and board compatibility |

| Streetwear consumers | Skate culture aesthetics: logos, loose fits, branded details |

| Youth & Gen Z | Comfort-driven with utility features and fashion edge |

They are typically styled with graphic tees, oversized hoodies, skate shoes (e.g. Vans, Nike SB), and beanies, reinforcing the subcultural connection. Collaborations between skate brands and fashion houses (e.g. Palace x Adidas, Supreme x Nike) have pushed skate joggers into the mainstream.

Production & Quality Control Insights

Manufacturing skate joggers for serious users involves stricter production protocols:

- Bartack reinforcements at high-stress points (pocket edges, crotch, side seams)

- Fabric abrasion testing (e.g. Martindale or Wyzenbeek) to verify durability

- Graded fit ranges that allow ease at hips/thighs with narrower ankle openings

- Panel matching across reinforced zones to maintain fabric grain direction and aesthetic

Additionally, batch testing for seam strength and elasticity retention is advised to ensure long-term performance under repeated stress.

Campus Joggers

Campus joggers are a timeless staple in student fashion, embodying a blend of relaxed fit, casual aesthetic, and versatile wearability. Originally popularized on American college campuses, these joggers are designed for all-day comfort—from dorm rooms and libraries to casual hangouts and coffee runs

Cultural Roots & Style Relevance

Campus joggers trace their origins to American university lifestyle wear in the late 20th century, where sweatpants became a symbol of comfort and academic ease. Over time, these joggers evolved into a mainstream fashion piece associated with:

- Youth culture and college branding

- Athleisure trends in Gen Z fashion

- “Study-core” or “preppy-comfort” aesthetics

Unlike performance joggers, campus joggers prioritize lifestyle over sport, often featuring university logos, embroidered patches, or school mascots as key decorative elements.

Fabric Characteristics

Comfort is the cornerstone of campus joggers. Key fabric choices include:

| Fabric Type | Properties |

|---|---|

| Brushed Fleece (Cotton-Poly) | Soft touch, mid-weight warmth, easy care |

| French Terry (100% Cotton or Cotton-Rich) | Lightweight with looped interior, breathable & cozy |

| Cotton-Spandex Blends | Added stretch for movement without sagging |

The GSM range usually falls between 240–300, providing a balance between insulation and breathability—perfect for transitional weather in academic settings.

Fit & Construction Features

Campus joggers are tailored for lounging, walking, and studying rather than athletic training. Construction typically includes:

- Mid to high-rise waistbands, often with exposed elastic or drawstrings

- Relaxed or slightly tapered leg fits for movement ease

- Cuffed or open hems, depending on regional preferences

- Side seam pockets for practicality, occasionally with zip closures

- Back patch pockets for a more laid-back aesthetic

- Interior brushed lining for extra warmth in colder climates

Some styles also include waistband branding, collegiate graphics, or woven label details to emphasize school spirit and nostalgia.

Target Demographics & Use Cases

| Segment | Primary Needs |

|---|---|

| University Students | Everyday wear, study sessions, campus events |

| High School Teens | Trend-forward comfortwear for after school |

| Young Professionals | Loungewear that feels elevated, not sloppy |

| Athleisure Shoppers | A mix of style, function, and comfort |

These joggers are typically paired with hoodies, oversized tees, varsity jackets, or sweatshirts, reflecting a relaxed and effortless look that’s suitable for modern campus culture.

Manufacturing & Branding Considerations

To meet demand from both B2B buyers (campus stores, college brands) and DTC brands, manufacturing campus joggers should factor in:

- Heat transfer or embroidery options for college branding

- Pre-washing treatments for shrink resistance and softness

- Reinforced bar tacks at pocket openings for durability

- Bulk production efficiency for seasonal back-to-school collections

- Gender-neutral grading to cater to all student segments

Campus joggers can also be easily adapted into limited-edition drops, with specific school colors or mascots printed for fanwear appeal.

Military Joggers

Military joggers draw inspiration from combat-ready attire but adapt it for everyday fashion and streetwear functionality. Characterized by rugged materials, multiple pockets, and structured silhouettes, these joggers combine utilitarian aesthetics with casual comfort—appealing to both fashion-forward consumers and those seeking durability in daily wear.

Historical Influence & Style Evolution

The military jogger is a modern reinterpretation of traditional cargo pants and BDUs (Battle Dress Uniforms). Key influences include:

- WWII and post-war army fatigues, known for their practicality and reinforced construction

- Tactical gear, featuring modular storage and ease of motion

- Contemporary urban fashion, especially in the menswear and streetwear categories

Unlike traditional joggers, military joggers are function-first, with design features that serve both aesthetic and practical purposes.

Fabrication & Durability

Military joggers prioritize rugged performance and resistance. Typical fabric choices include:

| Fabric Type | Features |

|---|---|

| Cotton Twill (260–320 GSM) | Heavy-duty, abrasion-resistant, breathable |

| Ripstop Nylon or Polyester | Reinforced weave for tear resistance and outdoor use |

| Spandex-Infused Blends | Adds flexibility without sacrificing durability |

| Water-resistant coatings (DWR) | Common for outerwear-inspired joggers |

Fabric finishing may include enzyme washing, stone washing, or reactive dyeing to give a vintage or distressed military look. Double-needle stitching is often used for reinforcement at stress points.

Design & Technical Construction

Military joggers often incorporate engineering-grade construction techniques, designed for both function and form:

- Elasticated or drawstring waistbands for comfort and adjustability

- Large utility pockets, including cargo, flap, and zippered versions

- Reinforced knee patches or darted knees for increased movement range

- Adjustable ankle cuffs, sometimes with toggles or Velcro for secure fit

- Topstitched paneling to emphasize structure and create a more “battle-ready” silhouette

- D-rings or tactical loops for attaching keys or accessories

Advanced versions may integrate hidden zip compartments, ventilation eyelets, or removable patches for customization.

Target Audience & Market Use Cases

Military joggers have found popularity in multiple consumer segments:

| Segment | Key Value Drivers |

|---|---|

| Streetwear consumers | Rugged aesthetic, bold silhouette, brand identity |

| Outdoor enthusiasts | Utility pockets, movement, durability |

| Workwear buyers | Functional style with comfort for light labor |

| Tactical/lifestyle | Military-inspired fashion with civilian wearability |

Brands often market these joggers under collections like “Urban Combat,” “Tactical Street,” or “Field Ready.” When combined with bomber jackets or techwear, they form a strong visual narrative that appeals to trend-aware consumers.

Manufacturing & Branding Considerations

Military joggers require elevated craftsmanship. Production must ensure:

- Reinforced stitching at all stress areas (seat, crotch, knee, pocket corners)

- Consistent pocket placement for symmetry and batch alignment

- Heavy-duty trims, such as YKK zippers, snap buttons, and utility webbing

- Custom dyeing or garment washing for military colorways (olive drab, sand, navy, camo)

- Brand positioning: consider storytelling around durability, heritage, or tactical performance

Private labeling options may include embroidered patch branding, laser-etched hardware, or limited edition runs to attract niche buyers and collectors.

Industrial Joggers

Industrial joggers represent the fusion of workwear durability and streetwear aesthetics. Designed to withstand demanding environments while offering everyday comfort, they take cues from construction apparel, utility gear, and modern fashion, making them a versatile option for brands targeting both function and form.

Workwear-Inspired Design Roots

Industrial joggers draw heavily from traditional mechanic pants, carpenter trousers, and industrial uniforms. Key inspirations include:

- Heavy-duty cargo pants with tool loops and hammer pockets

- Construction-grade materials like canvas, duck cloth, and twill

- Ergonomic patterns from utility and industrial safety wear

Rather than purely fashion-driven, these joggers are engineered to endure wear and tear, ideal for brands that want to offer functional fashion or cater to consumers who appreciate utility-driven design.

Material Selection & Functional Fabrication

The defining feature of industrial joggers is their reinforced construction. Common materials include:

| Fabric Type | Characteristics |

|---|---|

| Cotton Duck Canvas | Ultra-durable, abrasion-resistant, used in workwear |

| Heavy Twill (280–350 GSM) | Structured and strong, maintains shape over time |

| Ripstop Blends | Reinforced weave to prevent tearing |

| Stretch-infused Canvas (2–5% Spandex) | Allows mobility while preserving toughness |

Many industrial joggers are also treated for stain resistance, oil repellency, or UV protection, depending on their intended usage.

Technical Construction & Design Details

Construction is where industrial joggers shine. Key features often include:

- Double-layer knee panels for reinforcement in stress areas

- Bar-tacked pocket openings to prevent tearing from tool use

- Multiple utility pockets, such as carpenter loops, cargo, hammer straps, and back tool pockets

- Elastic cuffs or adjustable ankle cinches for safety and style

- High-strength triple stitching for longevity

- High-rise or mid-rise waistband with reinforced belt loops and/or drawcords

Designs can incorporate reflective tape, branded work tags, or even detachable components to enhance versatility.

Use Cases & Consumer Segments

Industrial joggers are suitable for both function-focused workers and fashion-forward consumers:

| Target Segment | Use Case |

|---|---|

| Creative professionals | Art studios, workshops, event setup crews |

| Urban utility wearers | Streetwear with rugged, masculine appeal |

| Light industrial workers | Non-heavy-duty labor (e.g., warehouse, logistics) |

| Fashion-forward users | Part of a techwear, gorpcore, or workwear-inspired look |

These joggers often cross into “workleisure” territory—a new segment blending professional functionality with comfort and daily versatility.

Manufacturing Considerations

Due to their structural complexity, industrial joggers require:

- Advanced stitching machinery, especially for heavy-weight fabric handling

- Strict quality control at tension points (knees, pockets, crotch)

- Durable trims such as YKK metal zippers, industrial-strength snaps, and workwear-grade buttons

- Accurate panel alignment, especially when using multiple layers or contrast panels

Many brands also opt for enzyme washes or garment dyeing to soften stiff fabrics while retaining the rugged appearance.

Brand Positioning & Differentiation

Industrial joggers are often marketed under terms like:

- “Urban Utility Pants”

- “Workwear Joggers”

- “Tactical Street Bottoms”

To stand out, brands can:

- Develop signature features like modular pocket systems or magnetic closures

- Collaborate with industrial sectors for authentic co-branded capsules

- Use eco-responsible fabrics with recycled canvas or organic cotton duck for sustainability narratives

- Highlight performance tests (abrasion resistance, tensile strength, etc.)

High-Street Joggers

High-street joggers embody the perfect balance between urban streetwear culture and premium fashion influences. Popular among style-conscious millennials and Gen Z, these joggers are not just casual pants—they’re a statement piece. Blending sleek silhouettes, elevated details, and runway-inspired elements, they reflect the trend-forward DNA of global fashion capitals like London, Paris, and Milan.

Fabric & Material Selection

High-street joggers often use premium, fashion-grade materials that elevate the product from casualwear to luxury:

| Material | Features |

|---|---|

| Modal or Tencel blends | Smooth hand-feel, drapability, premium sheen |

| High-GSM Ponte or Viscose-blend knits | Offers structure without stiffness |

| Satin or sueded finishes | Adds a refined visual texture |

| Bonded jersey | Ideal for tailored cuts with wrinkle resistance |

The emphasis here is on tactility and drape. Materials must look elevated but still allow ease of movement, ensuring that wearers experience both polish and comfort.

Design Language & Construction

High-street joggers are not defined by utility but by tailored silhouettes and designer details. Key features include:

- Tapered or carrot-leg cuts with precise ankle finishing

- Minimalist seams or side tuxedo stripes for elongation

- Extended waistband tabs, metal toggles, or hidden zips for elevated aesthetics

- Pin tuck front seams, pressed creases, or panel overlays to mimic suiting styles

- Luxury finishing like bar-tack stitching, embroidered logos, or laser-cut hems

While traditional joggers focus on comfort, high-street joggers are built like tailored trousers—with precision stitching, elevated trims, and high-end construction standards.

Brand Strategy & Consumer Appeal

High-street joggers target a very specific audience:

| Consumer Type | Motivation |

|---|---|

| Urban Professionals | Blending casual and polished in their everyday wardrobe |

| Fashion Enthusiasts | Seeking trend-driven silhouettes with premium construction |

| Influencer Culture | Prioritizing style visibility and curated aesthetics |

| Travel/City Lifestylers | Need for refined comfort during movement |

These joggers are often paired with oversized blazers, sleek sneakers, designer tees, or crop tops for Instagram-worthy looks. Many brands release them as part of “Elevated Essentials” or “Street Tailoring” collections.

Manufacturing Considerations

Creating high-street joggers demands precision and upscale workmanship:

- Fabric pre-treatment (e.g., enzyme wash, anti-pilling) to preserve texture and shape

- Panel alignment and seam matching to ensure clean lines

- Premium trims sourcing, including custom metal logos or matte-finish hardware

- Luxury fit standards—no puckering, minimal stretch distortion, no front bulging

- Tailored pattern grading, especially for taper and ankle fall

Because these joggers function closer to tailored pants than sportswear, they often follow suiting QC standards and demand refined construction techniques, such as blind hems or fused waistbands.

Differentiation in the Market

For brands looking to stand out in the high-street jogger segment:

- Use fabric innovation (e.g. silk-blend knits, recycled premium blends)

- Offer capsule collections with limited-edition drops and seasonal hues

- Emphasize narrative—such as “Modern Luxury Movementwear” or “From Runway to Sidewalk”

- Integrate branding subtly, e.g., tonal embroidery or interior label storytelling

- Collaborate with stylists or influencers to showcase curated looks

The category lends itself well to higher margins, aspirational branding, and style-first positioning—perfect for emerging fashion labels or DTC luxury startups.

Techwear Joggers

Techwear joggers are the embodiment of utility-driven fashion, born from the intersection of military functionality, urban survivalism, and futuristic minimalism. These joggers are not just garments—they are engineered tools designed to perform in modern cityscapes, harsh environments, and unpredictable weather.

Often associated with brands like ACRONYM, Guerrilla Group, and Nike ACG, techwear joggers serve both as style statements and technical gear, making them a favorite among fashion-forward individuals, digital nomads, and outdoor tech enthusiasts.

Fabric Engineering & Functional Textiles

Techwear joggers rely heavily on advanced textile technology. The fabrics used must provide multiple-layer functionality:

| Fabric Type | Technical Benefits |

|---|---|

| Nylon with DWR coating | Water-repellent, windproof, and abrasion-resistant |

| Softshell or 3-layer laminate | Offers breathability, weather resistance, and stretch |

| Ripstop stretch fabric | Reinforced tear-resistance with 2-way or 4-way stretch |

| CORDURA® or Schoeller® blends | Industrial-grade durability for urban or tactical applications |

Most techwear joggers are built to withstand outdoor elements, yet remain lightweight and flexible for urban mobility. Fabrics are often treated with anti-static, antimicrobial, or quick-dry coatings.

Design Philosophy & Key Construction Details

Techwear joggers follow a strict form-follows-function philosophy, meaning every design detail serves a real-world purpose. Hallmark design features include:

- Multiple cargo and utility pockets, often asymmetrical or zippered for secure storage

- Articulated knees and gusseted crotch for enhanced movement and mobility

- Hidden compartments or modular pouches for tools, phones, or EDC (everyday carry) items

- Elastic drawcord hems, Velcro ankle cuffs, or zip-off legs for multi-environment adaptability

- Bonded seams or laser-cut edges for a futuristic and minimalist finish

Silhouettes typically range from tapered tech-slim to drop-crotch designs for a cyberpunk aesthetic, influenced by both anime and military uniforms.

Target Users & Practical Use Cases

Techwear joggers cater to niche but growing user segments:

| Segment | Use Case |

|---|---|

| Urban explorers | Need lightweight, durable gear for all-weather commuting |

| Digital nomads | Prioritize function, mobility, and style during travel |

| Creative professionals | Appreciate the visual identity and future-forward aesthetic |

| Tactical gear enthusiasts | Use joggers for EDC, urban survival kits, or light field work |

| Style-first consumers | Drawn to techwear’s dystopian, ninja-core visual language |

These joggers are often marketed as “everyday armor” or “city-ready combatwear,” blending tactical readiness with urban fashion expression.

Manufacturing Considerations

Production of techwear joggers requires complex garment engineering and high-quality component sourcing:

- Precision cutting for articulated panels and ergonomic movement

- Reinforced seam construction—often flat-felled or double-stitched for durability

- Advanced hardware: YKK AquaGuard zippers, magnetic buckles, strap systems

- Multiple fit prototypes to accommodate both functionality and silhouette

- Durability testing: abrasion resistance, water repellency, stretch recovery

Each pair is almost like a gear kit, demanding a supply chain capable of low-margin, high-complexity production, often with smaller MOQs but higher price points.

Brand Differentiation & Collection Strategy

Techwear joggers offer strong opportunities for niche brand positioning:

- Develop signature pocket systems or modular accessories

- Co-brand technical fabric suppliers (e.g., “Crafted with Schoeller® Dryskin”)

- Build visual storytelling around cyberpunk, survivalism, or stealth mobility

- Limited drop strategies with serialized joggers to drive hype

- Collaborate with tech, gaming, or outdoor gear influencers

Because the aesthetic and function are tightly integrated, consistency in storytelling and utility is crucial to retain credibility within the techwear community.

Relaxed Lounge Joggers

Relaxed lounge joggers are the epitome of casual comfort, designed for moments of rest, recovery, and cozy living. Whether worn during a quiet weekend, after a long day of work, or while working from home, these joggers are engineered for ease of movement and a soft hand-feel—without sacrificing aesthetic balance.

Unlike performance or fashion joggers, relaxed lounge joggers are comfort-first garments, often featuring generous silhouettes, minimal structure, and ultra-soft fabrics. Their simplicity is their strength.

Fabrication & Material Focus

The hallmark of a great lounge jogger is its fabric composition. Comfort and breathability take priority, with common textile choices including:

| Fabric Type | Key Properties |

|---|---|

| Brushed French terry | Lightweight, moisture-wicking, and soft against the skin |

| Modal-blend knits | Silky hand-feel, great drape, and breathable |

| Bamboo viscose jersey | Naturally antibacterial, temperature-regulating |

| Cotton-poly fleece | Cozy warmth with added durability and shape retention |

| Tencel-spandex blends | Sustainable, luxuriously soft, and gentle stretch |

These materials are chosen for low GSM (lightweight), high breathability, and tactile softness—critical for garments worn for long periods in relaxed settings. Some styles also include peach-skin finishes for an ultra-soft surface.

Design & Construction

Relaxed lounge joggers prioritize freedom of movement and minimal garment pressure. While they are simple in appearance, key construction choices make a difference:

- Straight or wide-leg silhouettes to avoid leg constriction

- Elasticized or drawstring waistbands with soft internal casing

- No or minimal side seams for reduced skin irritation

- Deep slip-in pockets for phones, remotes, or essentials

- Ribbed ankle cuffs (optional)—used more in tapered lounge cuts

Some high-end versions include flatlock seams for a smoother interior, and double-needle stitching at stress points for long-term wear and wash durability.

Target Audience & Use Cases

Relaxed lounge joggers appeal across demographics, but dominate in three specific lifestyle segments:

| Segment | Use Case |

|---|---|

| Remote workers | All-day comfort while maintaining decent style |

| Homebodies & minimalists | Prefer softness, breathability, and loose fit |

| Wellness & self-care | Seek recovery wear for body and mind balance |

These joggers are also popular as unisex or gender-neutral products, especially when offered in extended sizing and inclusive marketing.

Manufacturing Considerations

Though simple in appearance, lounge joggers require precision in softness and stretch behavior:

- Fabric shrinkage control is crucial—lounge wear sees frequent washing

- Elastic waistband comfort must be tested for all-day wear

- Pattern grading should ensure relaxed fit without looking oversized

- Thread selection must match stretch levels to prevent breakage

- Loopback vs. fleece finishes must be chosen based on climate and season

Cutting efficiency is typically high due to simple shapes, making lounge joggers ideal for cost-effective production—particularly in modal or bamboo fabric categories where weight per unit can reduce shipping costs.

Brand Positioning & Growth Strategy

For fashion brands, lounge joggers serve as both entry-level comfort pieces and lifestyle branding tools. Strategies include:

- Bundle with hoodies or robes as cozy sets

- Eco-conscious capsule collections using bamboo or Tencel

- Lifestyle-driven storytelling around rest, balance, or home life

- Influencer collaborations with wellness coaches or sleep brands

- Subscription-based basics model to drive repeat sales

Relaxed lounge joggers are also ideal for private label expansion, offering high volume potential and strong customer loyalty due to fabric performance.

Couture Joggers

Couture joggers are the epitome of elevated athleisure—fusing luxury fashion techniques with the laid-back silhouette of classic jogger pants. Unlike casual or performance joggers, couture joggers are designed with a runway mindset, often featuring exquisite craftsmanship, fine fabrics, and high-end finishes typically reserved for designer collections.

These joggers represent a growing demand in the fashion industry: comfortable pieces that don’t compromise on exclusivity, design, or craftsmanship.

Fabrication & Material Innovation

Couture joggers start with premium-grade textiles. Unlike basic knits or poly blends, they rely on luxury fashion materials that require expert handling during production. Common choices include:

| Fabric Type | Characteristics |

|---|---|

| Silk charmeuse blends | Fluid drape, subtle sheen, breathable |

| Luxe wool or cashmere | Warm, structured, and elegant |

| High-density satin | Glossy, firm, and wrinkle-resistant |

| Stretch twill or ponte | Sculpted silhouette with high recovery and comfort |

| Jacquard or brocade | Textured detailing, ideal for elevated motifs or logos |

These materials often require interfacing, lining, or fusing to maintain the shape of the jogger silhouette without compromising drape or softness. Additionally, couture joggers may include embellishments like hand-stitched embroidery, beading, or metallic hardware.

Design & Construction Techniques

Couture joggers go beyond function—they’re architectural garments. Construction involves tailoring principles borrowed from trousers and couture dresses, applied to jogger silhouettes:

- Tailored waistband with hidden side zip, not drawstring or elastic

- Tapered or flared leg with pleating, darts, or front creases

- Side piping, tuxedo stripes, or satin inserts for visual elevation

- Invisible or covered seams to create a clean interior finish

- Lining or partial lining for luxury feel and form retention

- Embellishment techniques such as hand-applied pearls, crystals, or lace overlays

The production of couture joggers may involve multiple fittings, precise grading, and fabric tests to maintain luxury standards—especially when integrating multiple materials in one piece.

Target Market & Style Positioning

Couture joggers cater to fashion-forward luxury consumers, specifically:

| Segment | Preference |

|---|---|

| High-end fashion buyers | Seek originality, exclusivity, and statement wear |

| Celebrities & stylists | Use couture joggers for red carpet or fashion week |

| Designer brand followers | Expect elevated basics with storytelling value |

| Influencer-led fashion lines | Leverage couture joggers as signature pieces |

Couture joggers are not marketed as everyday wear—they’re positioned as luxury occasion-wear, runway athleisure, or evening-appropriate loungewear, often styled with structured blazers or formal tops.

Manufacturing & Production Considerations

Production requires a skilled development team and stricter process controls:

- Small-batch or made-to-order production is common due to high cost per unit

- Fabric cutting and seam alignment must be extremely precise for prints or embroidery

- Hand-finishing and embellishment increase labor time per unit significantly

- Fit testing and drape validation are needed for each fabric used

- Packaging must also reflect the luxury positioning—often including garment bags, tissue wrap, and branded boxes

These joggers are typically manufactured in specialized factories or studio ateliers, often in collaboration with fashion designers or artists.

Brand Strategy & Differentiation

Couture joggers allow brands to blur the lines between streetwear and haute couture, making them a key category for:

- Luxury brand extensions into casual wear

- Designer capsule drops featuring limited editions

- Collaborations with celebrities or artists for storytelling impact

- Fashion week runway moments that mix tailoring and casualwear

- Custom/private label projects for high-net-worth clientele

Some brands also use bespoke jogger services—letting VIP clients customize fabric, embroidery, or fit to reinforce brand exclusivity.

Collaboration Joggers

Collaboration joggers are more than just pants—they’re a canvas for storytelling, creativity, and brand synergy. Born from partnerships between fashion designers, artists, musicians, influencers, or even global corporations, these joggers represent limited-edition exclusivity and cultural impact. In a saturated athleisure market, collaboration joggers offer both brands and consumers something rare: novelty with meaning.

Conceptual Framework

The essence of collaboration joggers lies in co-branding strategy and cross-cultural design narratives. Whether it’s a high-fashion house teaming up with a sportswear giant (e.g., Gucci x Adidas), or an underground street artist collaborating with a boutique label, the purpose is clear: to blend distinct identities and create a product that wouldn’t exist without both voices.

These joggers often include:

- Dual-brand logos or custom emblems

- Tagline placement or signature motifs from both parties

- Prints, patches, or embroidery unique to the collaboration theme

- Limited edition numbering or collectible packaging

The value doesn’t come from materials alone, but from cultural relevance and design authenticity—which turns a jogger into a conversation piece.

Fabrication & Material Choice

Unlike commodity joggers, collaboration joggers often feature non-standard or experimental materials, which can include:

| Material Type | Functionality & Appeal |

|---|---|

| Organic cotton or recycled polyester | Aligns with sustainable brand partnerships |

| Tech fabrics (Dyneema®, Cordura®, or graphene) | Adds futuristic or functional edge |

| Hybrid blends (fleece + mesh, denim + nylon) | Symbolizes contrast and fusion |

| Custom-dyed or overdyed textiles | Enhances uniqueness and batch-to-batch variation |

In many cases, materials are sourced to reflect the identity of the guest collaborator—for example, an outdoor equipment brand might use weatherproof tech-woven fabric, while an artist might prefer raw denim or canvas for better print clarity.

Design & Construction Techniques

Collaboration joggers require high attention to design detailing. These are not mass-market silhouettes, and production is typically development-intensive, with special attention to:

- Unique pocket placements, like angled cargo with embossed logos

- Custom hardware, such as zipper pulls with brand initials or engraved buttons

- Contrasting panels, often showcasing opposing themes from each collaborator

- Heat-pressed graphic transfers or direct-to-garment (DTG) printing for detailed artwork

- Interior branding elements, like dual-logo woven labels or collectible hangtags

In many cases, joggers in this category follow drop culture production cycles, meaning short lead times but extremely high design accuracy.

Audience & Market Impac

Collaboration joggers appeal to multiple overlapping customer segments: